Pressure Washer Troubleshooting: How To Fix Common Problems

Solve common pressure washer problems with expert tips and step-by-step repair guidance

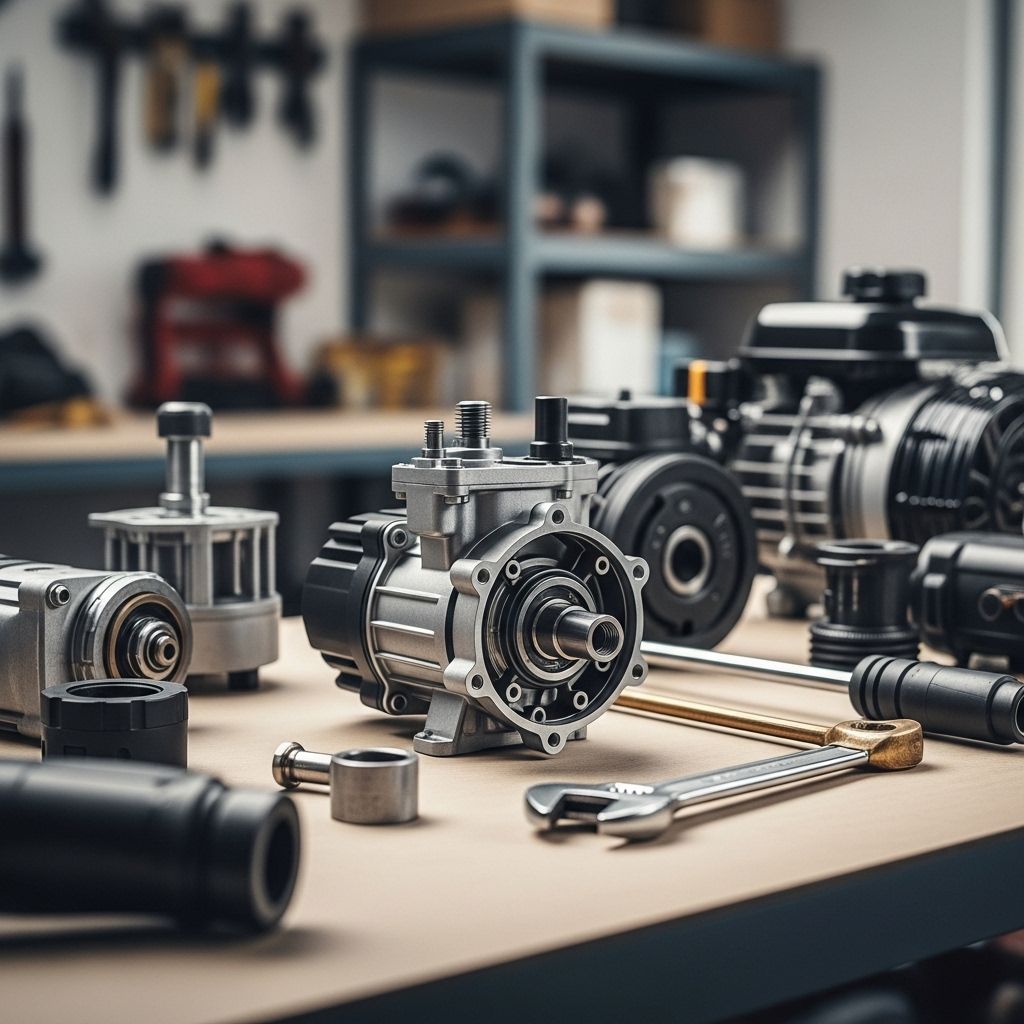

Image: HearthJunction Design Team

Common Pressure Washer Problems and How to Fix Them

A pressure washer is an invaluable tool for keeping your home’s exterior clean, but when it starts acting up, your cleaning projects can come to a frustrating halt. Whether you’re dealing with a machine that won’t start, inconsistent pressure, or mysterious leaks, this comprehensive guide will help you identify and resolve the most common pressure washer issues. With the right approach to troubleshooting, you can often avoid costly repairs or replacements and get back to your cleaning tasks quickly.

Understanding Your Pressure Washer

Before diving into specific problems, it’s helpful to understand the basic components that make up your pressure washer. Most pressure washers consist of:

- An engine or motor (gas or electric)

- A pump that creates pressure

- A high-pressure hose

- A spray gun and wand

- Various nozzles or spray tips

- An inlet water connection

Problems can occur in any of these components, and knowing how they work together will help you diagnose issues more effectively. Remember that gas and electric pressure washers may have different troubleshooting approaches for certain problems.

Pressure Washer Won’t Start

Electric Pressure Washer Starting Issues

If your electric pressure washer refuses to power on, start with these simple fixes:

- Check if the unit is properly plugged in and the outlet has power

- Inspect the power cord for damage or cuts

- Reset any tripped GFI (Ground Fault Interrupter) outlets

- Verify the on/off switch is functioning correctly

- Allow the motor to cool if it has overheated due to extended use

Many electric pressure washers have thermal protection that shuts them down when they overheat. Simply waiting 15-30 minutes may resolve the issue. If your unit has an auto-start/stop feature, ensure you’re pulling the trigger on the spray gun to activate the motor.

Gas Pressure Washer Starting Issues

For gas-powered machines, starting problems are often fuel-related:

- Check if there’s sufficient fresh fuel in the tank

- Verify the fuel valve is open

- Ensure the choke is in the correct position for starting

- Inspect the spark plug for damage or carbon buildup

- Clean or replace the air filter if it’s dirty

- Check if the engine oil level is adequate

Many gas engines have safety features that prevent starting if the oil level is too low. Always refer to your owner’s manual for specific starting procedures, as they can vary by model and manufacturer.

Low or No Pressure Problems

Perhaps the most common complaint about pressure washers is inadequate pressure. When your machine isn’t delivering the cleaning power you expect, consider these potential causes:

Check Your Spray Tips

The spray tip or nozzle has a significant impact on pressure. If you’re experiencing low pressure, first check if:

- You’re using the correct nozzle for your task (wider angle nozzles produce less pressure)

- The nozzle isn’t clogged with debris (clean it with a small wire or needle)

- The nozzle isn’t worn out or damaged

Remember that different colored nozzles indicate different spray angles and pressure levels. A 0-degree red nozzle delivers the highest pressure in a pinpoint stream, while a 40-degree white nozzle spreads the water over a wider area with less pressure.

Inspect the Water Supply

Inadequate water supply is another common cause of pressure problems:

- Ensure your garden hose is delivering sufficient water volume

- Check for kinks or blockages in the inlet hose

- Clean the water inlet screen/filter if it’s clogged

- Verify water temperature isn’t too high (exceeding manufacturer specifications)

Most residential pressure washers require at least 4 gallons per minute of water flow. Using a hose that’s too long or too narrow can restrict this flow and reduce pressure.

Pump and Unloader Valve Issues

If water supply and nozzles aren’t the problem, the issue might be with the pump or unloader valve:

- Check for air leaks in the inlet side of the pump

- Inspect pump seals for damage or wear

- Adjust the unloader valve if it’s misadjusted

- Look for worn or damaged pump components

The unloader valve recirculates water when the trigger is released and can be a common source of pressure problems. However, adjusting it requires caution as improper settings can damage the pump or create unsafe conditions.

Leaks and Water Problems

Water leaks not only reduce your pressure washer’s efficiency but can also lead to more serious damage if left unaddressed. Here’s how to tackle various leak issues:

Hose and Connection Leaks

Start by checking all connections and hoses:

- Inspect O-rings and replace any that are damaged or missing

- Tighten all connections, but avoid over-tightening

- Check the high-pressure hose for cracks or damage

- Verify that quick-connect fittings are fully engaged

Sometimes simply reseating connections or applying thread seal tape to threaded connections (where appropriate) can resolve minor leaks. Never use thread seal tape on quick-connect or O-ring fittings.

Pump Leaks

If the pump itself is leaking, you may be dealing with seal problems:

- Look for oil leaking from the pump (may indicate damaged oil seals)

- Check for water leaking from the pump body (often indicates worn water seals)

- Inspect for leaks between the pump and engine (could be damaged gaskets)

Pump seal replacement often requires disassembling the pump, which may be better handled by a professional unless you have mechanical experience. However, some pump seal kits are available for DIY repair if you’re comfortable with the process.

Pump Maintenance and Repair

Dealing with Milky Pump Oil

If you notice that your pump oil has a milky appearance, this indicates water contamination, which can seriously damage your pump if not addressed. This problem can be caused by:

- Damaged water seals allowing water into the oil chamber

- Cracked plungers or pistons

- Excessive humidity during oil changes

- A damaged water heat exchanger (on hot water models)

To fix this issue, you’ll need to change the oil and potentially replace the damaged seals. If the problem recurs shortly after an oil change, you likely have internal damage requiring seal replacement or possibly a pump rebuild.

Replacing Worn Packings

Packings are special seals that prevent high-pressure water from leaking around the plungers or pistons in the pump. When they wear out, your pressure washer may lose pressure or develop leaks. To replace packings:

- Purchase the correct packing kit for your specific pump model

- Disassemble the pump according to the manufacturer’s instructions

- Remove the old packings and carefully install new ones

- Reassemble the pump, ensuring proper alignment of all components

This repair requires mechanical skill and attention to detail. If you’re unsure, consult a professional pressure washer repair service.

Checking and Fixing the Pump’s Keyway

If your pressure washer runs but produces no pressure, the keyway connecting the pump to the engine may be damaged or misaligned. The keyway is a small metal piece that transfers power from the engine shaft to the pump.

To check and fix the keyway:

- Remove the pump from the engine

- Inspect the keyway for damage or misalignment

- Replace the key if damaged

- When reinstalling, consider making a small dent in one side of the key to wedge it securely in place

Never use tape or adhesives to secure the key, as these can fail and cause more significant damage.

Engine Problems and Solutions

For gas pressure washers, engine issues can prevent your unit from starting or cause it to run poorly. Common engine problems include:

- Stale fuel causing starting problems or rough running

- Dirty carburetor preventing proper fuel/air mixture

- Fouled spark plug interfering with ignition

- Clogged air filter restricting airflow

Basic engine maintenance can prevent many of these issues. Regularly change the oil, replace the air filter, and use fuel stabilizer when storing your machine for extended periods. If your engine runs roughly or surges, a carburetor cleaning may be necessary.

Pulsating Pressure Issues

If your pressure washer cycles between high and low pressure (pulsating), this typically indicates:

- Air in the pump or inlet line

- Insufficient water supply

- A partially clogged inlet filter

- Worn pump valves or seals

- Unloader valve problems

Start by checking your water supply and inlet filter, as these are the easiest to address. If those aren’t the issue, the problem may lie within the pump itself and might require professional attention.

Preventive Maintenance Tips

Regular maintenance can prevent many common pressure washer problems and extend the life of your machine:

- Always use fresh fuel in gas models and add fuel stabilizer when storing

- Change pump and engine oil according to the manufacturer’s schedule

- Clean or replace filters regularly

- Inspect hoses and connections for damage before each use

- Use pump protector or antifreeze when storing in cold climates

- Run clean water through the system after using detergents

Following these simple maintenance steps can save you time and money on repairs while ensuring your pressure washer is ready when you need it.

Frequently Asked Questions

Q: Why does my pressure washer start but then shut off?

A: This could be due to overheating, low oil level triggering a safety shutdown, fuel delivery problems, or a malfunctioning unloader valve. Check oil levels, allow the machine to cool down, and ensure adequate water flow to the pump.

Q: Can I repair a pressure washer pump myself?

A: Simple repairs like changing oil, replacing O-rings, or cleaning filters can be DIY projects. However, internal pump repairs require mechanical skill and specific tools. Consider professional repair for complex pump issues, especially if your unit is under warranty.

Q: How do I winterize my pressure washer?

A: To prevent freeze damage, disconnect all hoses, drain all water from the system, add pump antifreeze or pump saver product, pull the starter rope slowly (for gas models) to distribute the antifreeze, and store in a dry location. For gas models, either run the engine until the fuel is depleted or add fuel stabilizer to a full tank.

Q: Why is my electric pressure washer tripping the circuit breaker?

A: This could be due to using an extension cord that’s too long or too light gauge, a damaged power cord, an overloaded circuit, or a failing motor. Try plugging directly into an outlet on a dedicated circuit, and inspect the power cord for damage.

Q: Is it normal for a pressure washer pump to leak a small amount of water?

A: A very small amount of water dripping from the bottom of the pump (from the weep hole) can be normal as it prevents overheating. However, continuous or substantial leaking indicates worn seals that need replacement.

With proper troubleshooting and regular maintenance, your pressure washer should provide years of reliable service. When in doubt about complex repairs, consult your owner’s manual or seek professional assistance to avoid causing additional damage to your machine.

References

- https://theropshop.com/rugged-u/blog/having-pressure-washer-pump-issues-start-troubleshooting-here

- https://www.youtube.com/watch?v=cr9EOcQXwI8

- https://hotsyva.com/2024/03/05/10-common-pressure-washer-problems-and-how-to-fix-them/

- https://www.youtube.com/watch?v=HVblwZ6v0Y0

- https://nortexss.com/blogs/pressure-washing/pressure-washer-maintenance-handbook

Read full bio of Shinta