How to Run Pipes Through Walls and Floors: A Complete Guide

Expert tips secure plumbing while preserving structural strength and code compliance.

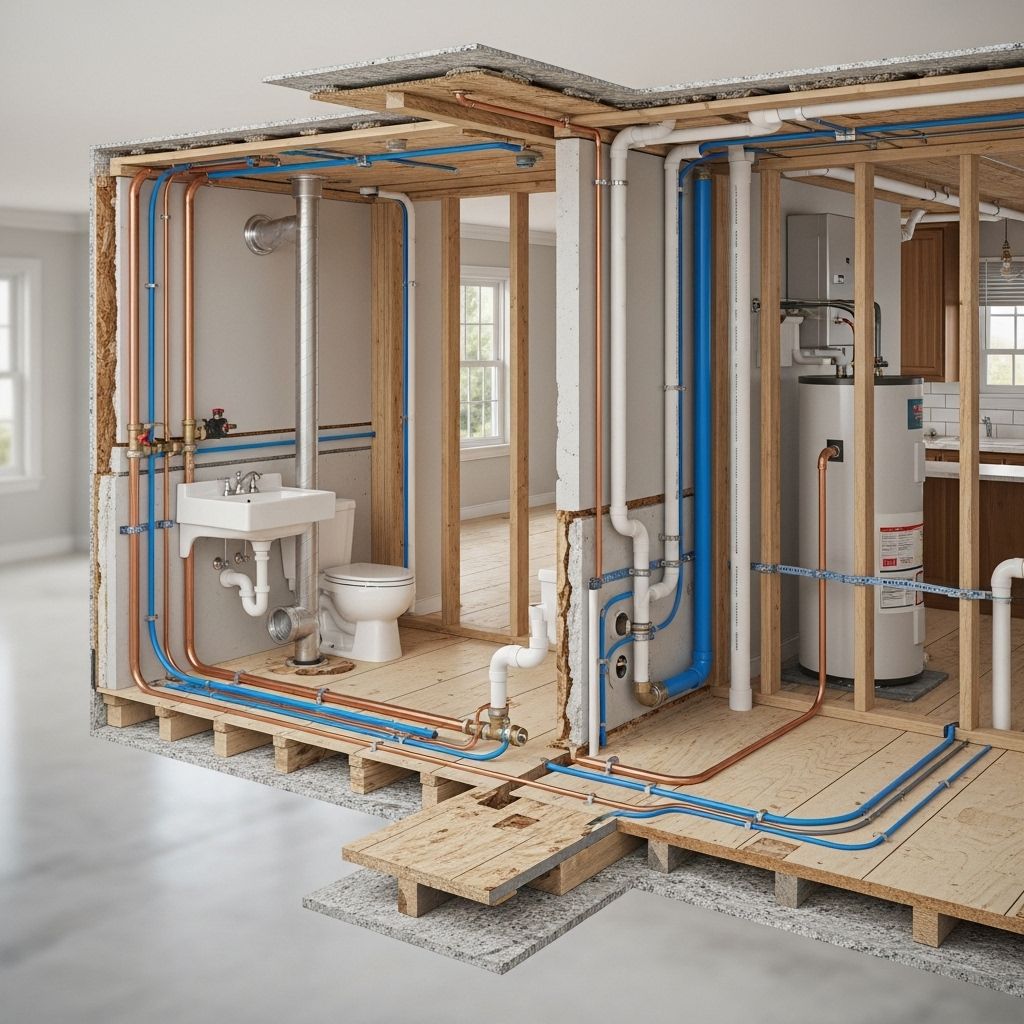

Running pipes through walls and floors is one of the most essential, yet challenging, tasks in home improvement plumbing. Whether you’re adding a new bathroom, relocating a washing machine, or replacing outdated lines, understanding the correct procedures is vital to ensure structural integrity, compliance with applicable codes, and a leak-free system. This practical guide covers all the crucial aspects—from selecting materials and making precise cuts to securing pipes and restoring surfaces—empowering you to execute plumbing projects with professional confidence.

Table of Contents

- Overview: Why Pipe Routing Matters

- Planning Your Pipe Route

- Choosing the Right Pipe Materials

- Essential Tools & Safety Equipment

- Marking, Measuring, and Cutting Openings

- Drilling and Notching: Protecting Structure

- Installing and Securing Pipes

- Sealing and Surface Restoration

- Building Codes and Inspections

- Tips, Mistakes to Avoid & Troubleshooting

- Frequently Asked Questions

Overview: Why Pipe Routing Matters

Rerouting or installing new pipes isn’t just about creating a path from Point A to Point B. Every decision you make—where to drill, how to support the line, even your choice of pipe material—impacts:

- Water efficiency and flow to fixtures

- Structural stability of walls and floors

- Long-term durability and maintenance requirements

- Compliance with local building codes

Improper pipe runs can lead to leaks, water damage, weak structures, and even expensive retrofits. Planning each step with care will save time and protect your investment.

Planning Your Pipe Route

Good plumbing starts with a well-thought-out plan. Before making any cuts or purchases, take the time to:

- Trace the shortest, straightest path from supply to fixture or from the fixture to drain pipes.

- Identify obstacles such as studs, joists, electrical wiring, ventilation ducts, and finished surfaces.

- Minimize the number of bends and turns. Gentle curves make water flow more efficient and reduce future maintenance issues.

- Locate key building framing members and mark areas where pipe can safely pass through without compromising structural strength.

- Check for existing plumbing lines—sometimes, leveraging or tapping into these can reduce labor and material costs.

Draw your proposed pipe route on the wall or floor using a pencil and a long square. Double-check measurements, especially where pipes will penetrate framing or intersect with other utilities.

Choosing the Right Pipe Materials

The choice of pipe material will determine the method of installation, the size of holes to be drilled, and the expected longevity of your plumbing.

| Pipe Material | Best For | Common Sizes | Pros | Cons |

|---|---|---|---|---|

| PEX | Water supply (hot/cold) | 1/2″, 3/4″, 1″ | Flexible, easy to install, freeze-resistant | Needs special fittings, not UV resistant |

| CPVC | Water supply (hot/cold) | 1/2″, 3/4″, 1″ | Resistant to corrosion and heat | Brittle over time, cannot be buried outdoors |

| PVC | Drains, vents | 1-1/2″ and up | Inexpensive, easy to cut | For drain use only, not for hot water |

| Copper | Water supply | 1/2″, 3/4″, 1″ | Durable, long-lasting, resists bacteria | Needs soldering, expensive |

| ABS | Drains, vents | 1-1/2″ and up | Strong, good for venting | Not approved everywhere |

Always check your local building code to see which materials are acceptable for your specific project.

Essential Tools & Safety Equipment

Gather all your tools before beginning. Recommended equipment includes:

- Pencil, tape measure, long level or square

- Drill and a selection of spade or hole saw bits (correct diameters for pipe size)

- Reciprocating saw or keyhole saw (for opening walls/floors)

- Pipe cutter or hacksaw

- Stud finder and utility knife

- Plumber’s tape (Teflon) and appropriate pipe sealant

- Pipe supports, clamps or hangers

- Eye protection, gloves, dust mask

- Drop cloths and shop vacuum for debris

Marking, Measuring, and Cutting Openings

Accurate marking and cutting ensures that your pipes will fit precisely and minimizes damage to finished surfaces.

- Locate Studs and Joists

- Use a stud finder to trace obstacles behind walls, floors, or ceilings.

- Mark the centerline of your intended pipe path with pencil or chalk.

- Lay Out Openings

- Where pipes change direction or emerge through drywall, outline their actual outside diameter plus at least 1/4 inch clearance.

- For grouped pipes (multiple lines in a chase), measure the entire cluster and plan accordingly.

- Cut Wall and Floor Surfaces

- Use a keyhole saw for drywall; reciprocating saw for wood subfloors.

- Carefully follow your lines—uneven holes can cause sealing issues later.

Drilling and Notching: Protecting Structure

Improperly drilled or notched joists and studs compromise the strength of your house. Always follow these safety principles:

- Minimum Distances: Drill holes at least 1 1/4 inches away from the edge of studs or joists to prevent nails or screws from piercing pipes during trim installation.

- Maximum Hole Sizes: Never cut a hole more than 40% of the width of a structural member. For example, in a 2×4 (actual width 3.5″), maximum hole is 1.5″.

- Hole Placement: In floor joists, drill holes near the center, not the top/bottom (which bears load); in wall studs, drill closer to the center, avoiding knots.

- Notching: Notches in load-bearing framing should generally be avoided except when permitted by code, and should not exceed one-sixth the member’s depth.

- Reinforcement: If you must notch or cut above code limits, reinforce with a steel plate (nail plate) or consult a structural engineer.

Installing and Securing Pipes

Placement details vary depending on whether you’re running pipes horizontally (through joists or studs) or vertically (through floors and ceilings):

- Dry Fit Pipes

- Assemble all pipe sections and fittings without gluing/soldering to ensure a good fit.

- Where pipes pass through multiple framing members, break the run into manageable lengths for easier installation.

- Secure Pipes

- Clamp or strap pipes every 4-6 feet horizontally and at every vertical floor/ceiling penetration to reduce vibration and prevent movement.

- Use plastic snap-in brackets for PEX; metal J-hooks for copper, and approved supports for PVC/CPVC.

- Connect Pipe Sections

- For PEX or CPVC use push-fit or crimp-on fittings. For copper, use sweat solder joints.

- Seal threaded joints with appropriate tape or sealant.

- Double-check every joint for cleanliness and correct orientation before final tightening or soldering.

- Test the System

- Before closing up walls or floors, turn on water and check every visible joint for leaks.

- If installing drain lines, pour water into the uppermost opening to check for leaks and proper drainage.

Sealing and Surface Restoration

Once all pipes are installed and checked:

- Seal wall or floor penetrations with expanding foam, fire-rated caulk, or other approved material. This helps block drafts, pests, and fire spread.

- Restore drywall or flooring using patch kits or replace sections as needed. Prime and paint to match the existing surface.

- For larger repairs, consult a finish carpenter or drywaller for best results.

Building Codes and Inspections

All plumbing work must comply with local building codes. Check for:

- Permits required before beginning work

- Maximum number of fixtures per pipe size

- Pipe support requirements and approved materials

- Firestopping specifications for penetrations

Schedule an inspection before any part of the pipe is closed inside walls or floors. Inspectors will look for:

- Correct pipe size and material

- Proper spacing and support

- Secure joints and no leaks

Tips, Mistakes to Avoid & Troubleshooting

- Label All Lines: Use colored tape or permanent marker to indicate hot, cold, and drain lines behind walls.

- Don’t Over-tighten Fittings: Too much torque can crack pipe, especially plastic types. Use torque guidelines for fittings.

- Avoid Drilling into Electrical Wiring: Always double-check locations with a multi-scanner before drilling.

- Allow for Expansion and Contraction: Install slip joints or expansion loops as needed to accommodate temperature changes.

- Slope Drain Lines Correctly: For drain pipes, use the standard 1/4 inch drop per 1 foot of horizontal run to ensure proper drainage.

- Shut Off Water: Always turn off main supply before beginning any work.

Frequently Asked Questions (FAQs)

What’s the best way to run water lines through an exterior wall?

Pipes in exterior walls are vulnerable to freezing. If unavoidable, insulate both the pipe and the wall cavity thoroughly and use pipe sleeves to allow for movement.

How do I avoid damaging floor joists when drilling for pipes?

Drill holes centered along the neutral axis of the joist, typically the center third of its height. Never notch the top or bottom unless directed by an engineer.

Which is better: PEX or copper for home plumbing?

PEX is easier to install, less expensive, and more freeze-tolerant. Copper lasts longer and can be used outdoors, but requires soldering and is more expensive.

Can I run pipes horizontally through load-bearing walls?

Yes, if you keep holes within code-specified limits and reinforce with nail plates to prevent drywall screws or nails from puncturing pipes after installation.

What permits do I need to run new pipes?

Nearly all plumbing projects that alter existing pipes or add new lines require a permit. Contact your local building department before starting work.

How do you test for leaks before closing up walls?

Turn on water pressure and inspect every joint. Many plumbers will leave system pressurized and monitor gauge over hours to confirm there are no slow leaks.

What should I do if I encounter a structural framing component?

Reroute the pipe if possible. If not, consult a structural engineer or a qualified contractor before cutting any main structural element.

Key Takeaways

- Plan routes before you cut, accounting for obstacles and necessary clearances.

- Always follow code for hole sizing and placement in framing.

- Choose pipe material suitable for your application and local code.

- Secure pipes to prevent future movement and leaks.

- Never skip inspections—they protect you and your home’s value.

With careful preparation, the right materials and tools, and attention to detail, you can successfully run pipes through walls and floors for any home project.

References

- https://www.finehomebuilding.com/project-guides/plumbing/running-pipes-through-walls-ceilings-and-floors

- https://splashplumbing.com/how-are-water-lines-run-in-a-house-a-comprehensive-guide-to-installation-and-layout/

- https://www.youtube.com/watch?v=Hjzl00pBrZs

- https://innovativeplumbingpros.com/where-should-you-run-your-plumbing-pipes/

- https://www.thisoldhouse.com/plumbing/21014914/from-the-ground-up-plumbing

Read full bio of medha deb