How to Install an Electrical Subpanel: Step-by-Step Guide for Homeowners

Expand home circuits confidently with clear planning, precise wiring, plus code checks.

How to Install an Electrical Subpanel

Installing an electrical subpanel is a practical way to expand your home’s electrical system, especially if you’re adding new circuits for additions, garages, workshops, or major appliances. This in-depth guide walks you through every step, from planning and permits to wiring and testing, enabling you to understand the process and safely manage this essential upgrade. Always prioritize safety, and consult a licensed electrician whenever you’re uncertain about procedures or local regulations.

Table of Contents

- What Is an Electrical Subpanel?

- When Should You Add a Subpanel?

- Planning for Subpanel Installation

- Tools and Materials Needed

- Step-by-Step Installation Guide

- Subpanel Wire Sizes

- Common Mistakes and Troubleshooting

- Safety and Code Compliance

- Frequently Asked Questions (FAQs)

What Is an Electrical Subpanel?

An electrical subpanel is a small service panel that distributes power from the main service panel to specific sections of your home or outbuildings. Subpanels are ideal for managing additional circuits, particularly when:

- Adding significant electrical loads (e.g., for remodeled spaces, workshops, or new appliances).

- Improving organization and troubleshooting by grouping related circuits together.

- Extending power to distant locations, reducing the amount of wiring from the main panel.

When Should You Add a Subpanel?

Consider installing a subpanel if your main panel is full or when powering remote areas like:

- Barns, sheds, or detached garages

- Home additions (e.g., finished basements, ADUs)

- Heavy equipment or high-wattage appliances (e.g., HVAC, kilns, EV chargers)

Subpanels are most useful when:

- The main panel lacks space for additional breakers.

- You want to localize breaker access in a separate area.

- Reducing voltage drops by shortening branch-circuit wire runs from the main source.

Planning for Subpanel Installation

Proper planning is essential for safe and code-compliant subpanel installation. Key planning steps include:

- Determine Load Requirements: Calculate the combined amperage of all circuits you intend to power.

- Choose the Correct Subpanel Size: Most homes opt for 60- or 100-amp subpanels, but the exact size depends on projected use. A 100-amp, 24-space panel offers flexibility for future needs.

- Location:

- Dry, easily accessible space (e.g., basements, garages, utility rooms)

- At least 30 inches of clearance in front and 4-5 feet above the floor for comfortable operation

- Check local building codes for minimum clearances and placement regulations

- Permits and Inspections: Secure needed permits from your local building authority before starting. Subpanel additions typically require inspection post-installation.

- Feeder Route: Plan the wiring route from main panel to subpanel, accounting for obstacles and total wire length.

Tools and Materials Needed

- Circuit tester or multimeter

- Screwdrivers (flat and Phillips head)

- Wire strippers and cutters

- Power drill (for mounting subpanel box)

- Level and tape measure

- Feeder cable (type and gauge determined by load and distance)

- Subpanel with breaker spaces (as sized in planning)

- Appropriate circuit breakers (20A, 30A, etc.)

- Grounding rods and connectors (for detached structures)

- Fish tape or pull cords (for running cable)

- Electrical tape, wire nuts, terminal lugs

- Labels for circuits

- Permits (from local authorities)

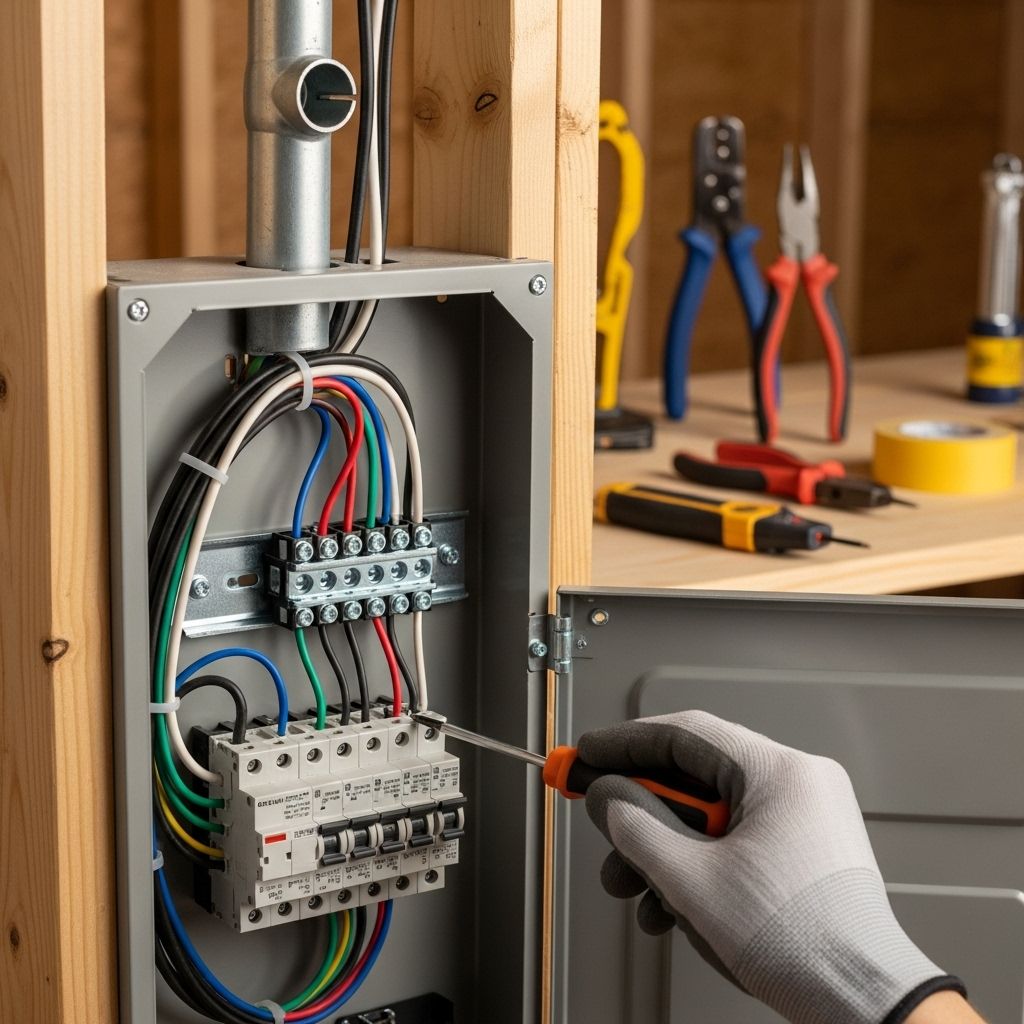

Step-by-Step Installation Guide

1. Plan the Subpanel Placement

- Select a suitable, dry, and accessible wall location for mounting the box.

- Mark where the subpanel will be installed. Ensure proper height and surrounding clearance (minimum of 30 inches in front and about 6.5 feet max height to top of the panel).

2. Obtain Necessary Permits

- Contact your local building or electrical department to acquire required permits.

- Make sure to schedule the inspection, which may be required before and after installation.

3. Mount Subpanel Enclosure

- Cut an opening in the drywall or mount to the wall with screws or anchors.

- Ensure enclosure is level and firmly attached using angle supports or backing as needed.

- Remove front panel/cover plate for access to interior lugs and bus bars.

4. Install the Feeder Breaker in Main Panel

- Turn off the main power at the service panel.

- Install a double-pole breaker sized for your subpanel (e.g., 60A breaker for 60A panel).

- Route feeder cable (with hot, neutral, and ground wires) from main panel to the new subpanel. Use proper cable (SER, conduit with THHN, etc.)

5. Run and Secure Feeder Cable

- Route feeder wire cleanly and securely through conduit or along framing as required by code—for detached structures, this may mean underground rated wire.

- Use bushings and connectors for cable entry and exit points to prevent abrasion.

6. Ground the Subpanel Correctly

- For detached subpanels, drive grounding rods outside the structure and connect with grounding wire.

- In all subpanels, connect ground wire to ground bus bar inside panel. Keep neutral and ground wires separate—remove any bonding screws or straps between neutral and ground within the subpanel.

- In attached structures, connect ground from main panel to ground bus in subpanel.

7. Connect Neutral and Hot Wires

- Securely connect hot feeder wires to main lugs or main breaker in the subpanel.

- Connect the neutral feeder wire to the neutral terminal bus. Ensure neutral bar is isolated from ground.

- Double-check that lugs/terminals are tightened to recommended torque settings per subpanel specifications.

8. Install and Wire Circuit Breakers

- Insert and secure breakers of appropriate amperage for each new branch circuit.

- Run branch wires (e.g., 12 AWG for 20A circuits) for outlets, lights, appliances, etc., from subpanel breakers to each endpoint.

- Carefully label each wire and breaker for ease of identification and future troubleshooting.

9. Connect Feeder to Main Panel

- With power off, connect each feeder wire (hot, neutral, ground) from the subpanel to the matching terminals in the main panel.

- Double-check polarity and all connections. Tighten to specified torque.

- Restore power and conduct initial tests on subpanel functionality.

10. Arrange Final Inspection

- Contact your local building inspector for the required final review and sign-off.

- Correct any issues identified before regular operation.

Subpanel Wire Sizes

Wire size is dictated by panel amperage and the length of the run:

| Subpanel Amperage | Copper Wire Size (up to 100ft) | Aluminum Wire Size (up to 100ft) |

|---|---|---|

| 60 Amps | 6 AWG | 4 AWG |

| 100 Amps | 3 AWG | 1 AWG |

Note: Always check the National Electrical Code (NEC) and local codes for requirements. Increase wire size for long runs to counteract voltage drop.

Common Mistakes and Troubleshooting

- Neutral-Ground Bonding Error: In a subpanel, never bond neutral and ground. They must be isolated to prevent stray current hazards.

- Undersized Feeder Wires: Using wire too small for load leads to overheating and fire risks. Refer to ampacity tables and plan with margin.

- Poor Grounding: Skipping or incorrectly installing ground rods leaves the system at risk in a fault.

- Sloppy Circuit Layouts: Bundle, label, and organize wires clearly for easy maintenance. Avoid overfilling panel beyond designed capacity.

- Code Violations: Always pull permits and have work inspected. DIY errors can result in rejected insurance claims—and serious safety risks.

Safety and Code Compliance

- Always shut off main power before working in any panel.

- Use a voltage tester to verify de-energization before touching wires.

- Wear insulated gloves and safety goggles.

- Follow local codes for subpanel size, wiring method, and grounding requirements.

- Never exceed the panel’s rated capacity for breakers or total amperage.

- Schedule an inspection with your local authority after installation.

- If unsure, consult a licensed electrician—mistakes can be dangerous or fatal.

Frequently Asked Questions (FAQs)

Q: Do I need a permit to install a subpanel?

A: In most areas, a permit is required for subpanel installation. This ensures compliance with safety codes and usually requires an inspection.

Q: How do I size my subpanel and wires?

A: Subpanel size depends on combined load calculations (total expected amperage). Wire size is determined by the amperage and the run’s distance (see the table above).

Q: Can I bond the neutral and ground in a subpanel?

A: No; neutral and ground must be isolated in all subpanels, to avoid safety hazards like stray currents.

Q: What are the main advantages of a subpanel?

A: Subpanels make remote circuits more manageable, tidy up circuit organization, reduce wire runs from the main panel, and support future expansion.

Q: When do I need ground rods at the subpanel?

A: For a detached structure, install ground rods at the subpanel. For attached subpanels, grounding is continuous from the main panel in accordance with local electrical codes.

Q: Can I install a subpanel outdoors?

A: Yes, but you must use an outdoor-rated subpanel enclosure, weatherproof conduit, and all wiring must meet exterior installation codes.

Final Notes

Upgrading your home’s electrical system with a subpanel is a project that requires careful planning, technical skill, and respect for safety codes. While this guide provides you with a thorough overview of the process, always weigh DIY ambitions against safety risks.

Electrical work should be performed by or inspected by a licensed professional to ensure your upgrades are safe, code-compliant, and reliable for years to come.

References

- https://voltaelectricinc.com/blog/guide-to-sub-panel-wiring-safety-wire-sizes-installation-tips/

- https://backyardoas.com/blogs/garage/how-to-install-sub-panel-in-detached-garage

- https://www.youtube.com/watch?v=uThjbVDcpxo

- https://www.youtube.com/watch?v=gfaw-XAvn4M

- https://plumbing-united.com/blog/installing-subpanel-homeowners-guide/

- https://www.electrical-online.com/subpanel-installation/

Read full bio of Sneha Tete