How to Safely Ground Electrical Wires: Step-by-Step Instructions

Secure your circuits to reduce shock risks, prevent fires, and protect valuable devices.

How to Ground Electrical Wires: A Step-by-Step Homeowner’s Guide

Effective electrical grounding is essential to a safe and reliable home electrical system. Grounding prevents electrical shocks, reduces fire risks, and helps protect appliances and devices from voltage surges. This guide will walk you through the fundamentals of grounding, its importance, a list of required materials, as well as clear, step-by-step instructions for grounding electrical wires in your home.

Why Is Electrical Grounding Necessary?

Electrical grounding provides a direct, low-resistance path for stray or fault currents to travel safely into the earth. This process:

- Protects people and pets from potential electrical shock.

- Prevents electrical fires caused by stray current and arcing.

- Shields sensitive appliances from voltage surges and lightning strikes.

- Ensures breakers and fuses trip in case of a fault, shutting off dangerous circuits.

Without proper grounding, electrical systems are vulnerable to hazardous faults that could damage property or endanger lives.

Understanding Grounding Basics

Grounding an electrical system involves connecting certain parts of the wiring—including metal boxes and panels—to the earth using conductive materials, typically copper wire and rods. Here are some key grounding components:

- Grounding Electrode Conductor (GEC): The wire that runs from the service panel to the ground rod (or other electrode).

- Ground Rod: A long metal rod (often copper or galvanized steel) driven deep into the earth to dissipate electrical current safely.

- Bonding: Connecting all metal parts (boxes, conduit, panels) together to ensure any stray current flows directly to ground, not through people or pets.

- Grounding Bus Bar: A terminal inside the main service panel where all ground wires connect.

When and Where Is Grounding Required?

The National Electrical Code (NEC) requires all main service panels to be grounded, with branch circuit grounds provided for all non-metallic sheathed cables (e.g. NM or “Romex”), and all metal boxes or conduit in the system properly bonded to ground. Subpanels and certain appliances may have additional grounding requirements.

- Always ground new or updated circuits.

- Repair or improve grounding during any major electrical upgrade.

- Consult local codes for specific requirements. NEC sets the baseline, but local authorities may have stricter rules.

Tools and Materials Needed for Grounding Electrical Wires

- Ground rod (at least 8 feet long, copper or galvanized steel per local code)

- Copper grounding wire (usually bare, size per code—often #6 AWG for homes)

- Ground rod clamp

- Wire strippers

- Sledgehammer or hammer drill with ground rod driver attachment

- Multimeter (capable of measuring resistance in ohms)

- Screwdrivers

- Protective gloves and goggles

Step-by-Step Guide: How to Ground Electrical Wires

Step 1: Plan the Grounding System

Review the location of your main electrical service panel. Select a grounding point outdoors, close to the panel, and ensure the soil is unobstructed (avoid rock or dense clay). Mark utility locations before digging or driving a ground rod.

Step 2: Drive the Ground Rod

- Position the ground rod upright at your chosen site. It must be sunk at least 8 feet into the earth, with about 6 inches left above ground for connection.

- If soil is hard or rocky, dig a shallow pilot hole to start. In difficult terrain (bedrock), install the rod at a 45-degree angle or bury it horizontally in a trench at least 30 inches deep.

- Use a sledgehammer or hammer drill to drive the rod. Keep it as straight as possible for best conductivity.

Step 3: Attach the Ground Wire to the Ground Rod

- Strip about 6 inches of insulation from one end of your copper grounding wire using a wire stripper.

- Secure the stripped wire to the exposed portion of the ground rod with an approved ground rod clamp. Make sure the connection is clean and tight.

Step 4: Connect the Ground Wire to the Service Panel

- Route the other end of the grounding wire to the main service panel.

- Strip about 6 inches of insulation.

- Connect the wire to the grounding lug or bus bar. This is usually marked inside the service panel and may be near the neutral bar. Ensure a solid, tight connection.

- SAFETY WARNING: ONLY perform work inside electrical panels if you have experience and have shut off the main breaker. When in doubt, hire a licensed electrician.

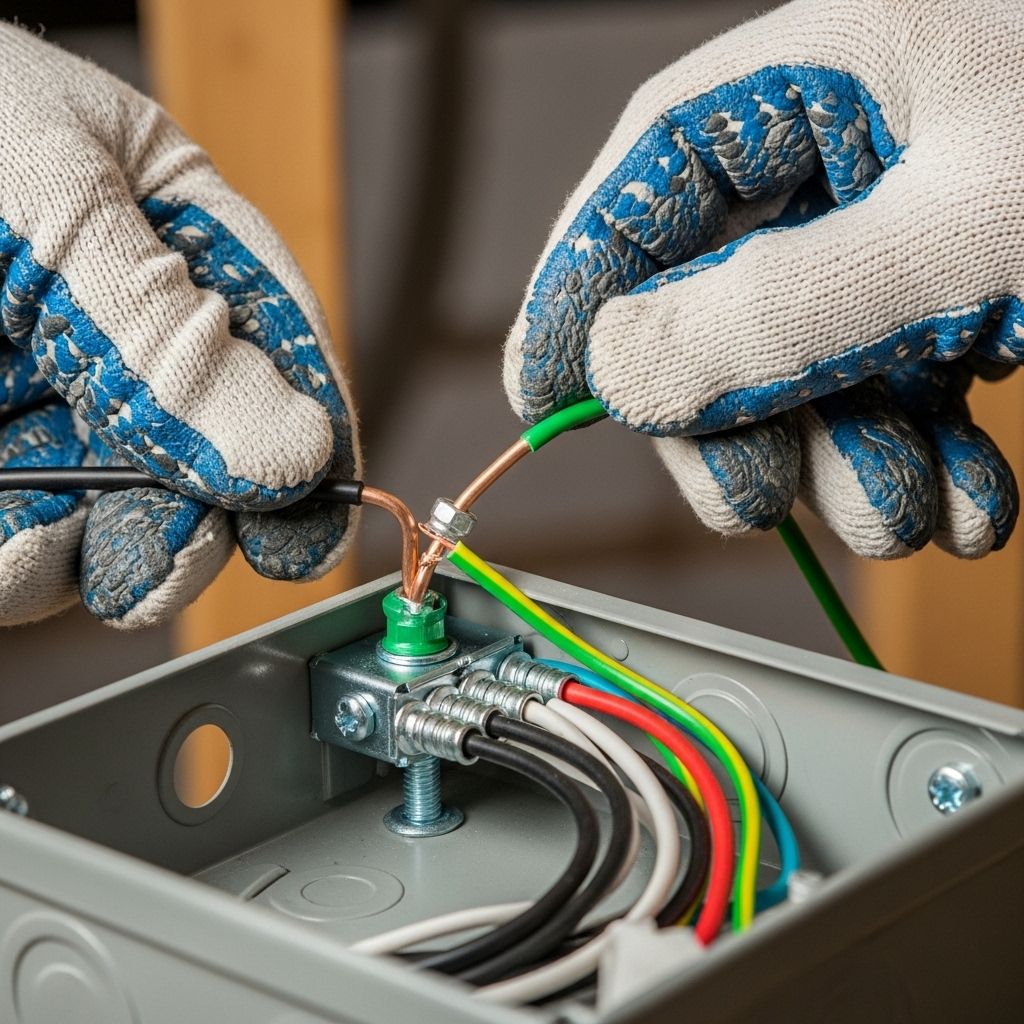

Step 5: Bonding Metal Boxes and Conduits

- To prevent stray current from energizing metal boxes, run a bare or green insulated ground wire from the panel’s ground bus to each metal junction box and receptacle.

- Use green grounding screws or grounding clips to secure the wire inside boxes.

- If metal conduit (EMT) is used, ensure proper connections at all joints for continuous bonding.

Step 6: Test Ground Connections

After making all connections, confirm effectiveness:

- Set your multimeter to resistance (ohms).

- Place one probe on the ground rod and another on the panel’s ground bus.

- You should see a reading near zero ohms, indicating a solid connection. High resistance readings may require inspecting connections or driving the rod deeper.

Step 7: Final Safety Checks

- Check all connections are tight and secure.

- Verify there are no exposed wires. Cover exposed ends with wire nuts or wrap with electrical tape as needed.

- Ensure the ground rod is not a tripping hazard and is clearly marked if located in a high-traffic area.

- Turn the main circuit breaker back on and test the system.

Special Grounding Scenarios and Code Considerations

Some situations require additional or alternative grounding techniques:

- Multiple Rods: If ground resistance is above 25 ohms after a single rod, NEC requires a second rod installed at least 6 feet away and connected with copper wire.

- Horizontal Electrodes/Grids: In areas with shallow soil or bedrock, you may need to install horizontal rods or run a ground grid (strip or wire buried in a trench) for improved effectiveness.

- Improving Soil Conductivity: In dry or sandy soil, add water and salt around the ground rod to lower resistance. Always ensure that local code permits this method before proceeding.

| Component | Material | Typical Size |

|---|---|---|

| Ground Rod | Copper, copper-clad steel, or galvanized steel | 8 ft x 5/8 in (minimum) |

| Ground Wire | Bare copper | #6 AWG (for most homes) |

| Ground Clamp | Brass or bronze | Size to fit rod |

| Panel Ground Lug | Brass or copper | Per panel specifications |

Grounding for Outlets, Switches, and Fixtures

Beyond the main panel, grounding must extend to outlets, light fixtures, and appliances:

- For non-metallic wiring (Romex): Use the dedicated bare ground wire and connect it to each grounding terminal.

- For metallic boxes: Ensure a ground wire is attached to the box via a green screw, grounding clip, or ground pigtail.

- For older homes without grounds: Upgrades strongly recommended for safety, especially before installing GFCI or AFCI outlets.

Troubleshooting Common Grounding Problems

- Loose Connections: Periodically tighten clamps and terminals.

- Corrosion: Inspect for rust or degradation, especially outdoors, and replace affected parts as needed.

- High Resistance: If measuring resistance greater than 25 ohms, add rods or improve soil contact.

- Physical Damage: Check for signs of wear, especially after construction or landscaping near the grounding system.

Electrical Grounding FAQs

Q: What is the difference between ‘grounding’ and ‘bonding’?

A: Grounding connects the electrical system to the earth to dissipate unsafe voltages, while bonding connects metal parts of the wiring system together to ensure there are no dangerous voltage differences between them.

Q: Can I ground an outlet if my home’s wiring has no ground wire?

A: It may be possible, but it’s complex—an electrician may run a new ground wire from the outlet to the panel’s ground bus. Modernizing ungrounded wiring greatly improves safety and is highly recommended for any upgrades.

Q: How deep does the ground rod need to go?

A: NEC dictates at least 8 feet in soil. In rocky or shallow-soil areas, a 45-degree angle or a horizontal trench at least 30 inches deep is permissible. Always refer to local code enforcement for unique situations.

Q: How do I know if my system is properly grounded?

A: Use a multimeter to test grounding resistance from the panel to rod; the reading should be near zero ohms. High readings indicate poor connections. Regular professional inspections also help ensure ongoing safety.

Q: Do I need to use two ground rods?

A: Only if one rod fails to produce less than 25 ohms of resistance, as measured by a multimeter. If so, NEC requires a second rod placed at least 6 feet away and bonded together with copper wire.

Final Tips for Electrical Grounding Safety

- Always shut off all power before starting work on any electrical system.

- Don’t attempt electrical grounding upgrades if you lack experience—consult a licensed electrician for your safety.

- Take time to inspect grounding systems annually and after any construction work nearby.

Properly grounding your home’s electrical system is not just a regulatory requirement—it’s a critical safety practice that can protect you, your family, and your property for years to come.

References

- https://threecrownselectric.com/how-to-ground-an-electrical-panel/

- https://safety.army.mil/Portals/0/Documents/ON-DUTY/WORKPLACE/ELECTRICAL/Standard/Leaders-Guide-to-Grounding-and-Bonding.pdf

- https://www.finehomebuilding.com/project-guides/wiring/grounding-basics

- https://www.youtube.com/watch?v=P-W42tk-fWc

- https://www.youtube.com/watch?v=M5xXIG2MEpM

Read full bio of medha deb