How to Connect New Pipes to Old Lines: A Step-by-Step Guide

Create durable, leak-free joints across various materials with confidence.

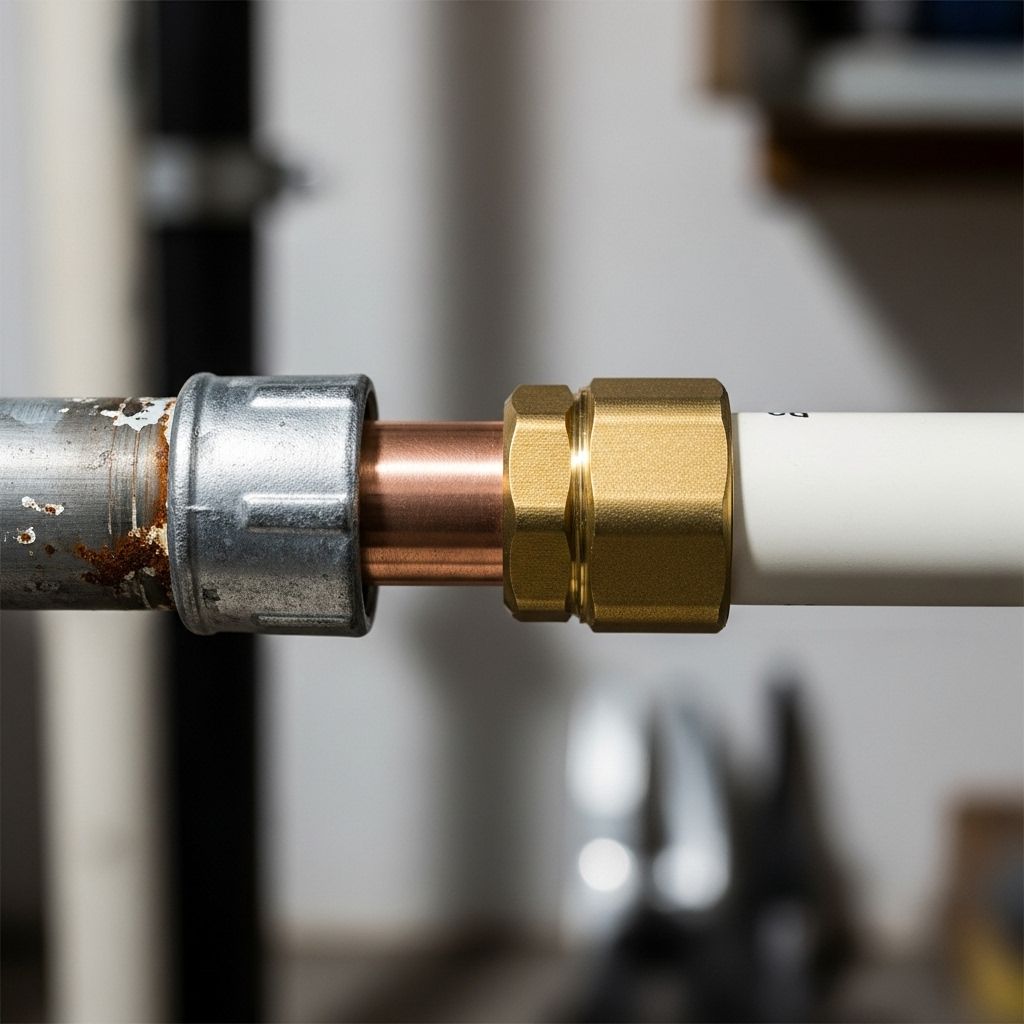

How to Connect New Pipes to Old Lines

Upgrading or expanding your home’s plumbing system often means connecting new pipes to existing lines. Whether you’re renovating a bathroom, installing a new kitchen sink, or updating an old drain, knowing the right way to join different types and ages of pipes is key to ensuring leak-free performance and code-compliant results. This comprehensive guide breaks down the step-by-step process of connecting new pipes to old plumbing lines, covering preparation, tools, safety, common scenarios, and troubleshooting tips.

Understanding the Basics of Plumbing Connections

Before starting any project, it’s important to recognize that plumbing systems in older homes may vary widely: you could encounter cast iron, copper, galvanized steel, or even lead pipes alongside newer PVC, ABS, or PEX materials. Each pipe type requires specific connection methods and compatible fittings. Success depends on using the right tools and materials for your particular scenario, as well as understanding plumbing codes and ensuring secure, water-tight joints.

Main Types of Plumbing Pipes

- Copper — Durable, often used for water supply lines.

- Galvanized steel — Common in older homes, but prone to corrosion over time.

- Cast iron — Sturdy, heavy, typically used in drains and vent stacks.

- PVC/ABS — Modern plastic pipes used for drain, waste, and vent lines.

- PEX — Flexible option popular for new water supply installations.

Preparing to Connect New Pipes to Old Lines

Proper preparation is critical to a successful connection. Rushing this step can lead to leaks, clogs, or failed connections later.

Essential Tools and Materials

- Pipe cutter or hacksaw (for metal or plastic pipes)

- Measuring tape and permanent marker

- Files or reamers for smoothing pipe edges

- Pipe cleaning brush or sandpaper

- PVC cleaner/primer and solvent cement (for plastic pipes)

- Pipe wrenches or adjustable pliers

- Fittings and couplings appropriate for both old and new pipe materials

- Teflon tape or joint compound (for threaded connections)

- Bucket and towels (to catch residual water)

- Safety goggles and gloves

Turn Off Water and Drain Lines

Always shut off the water supply and open nearby faucets to drain any water from the lines before cutting into existing pipes. For drain lines, avoid working when water is likely to flow through or when household use is high.

Step-by-Step: Connecting to Existing Pipes

1. Measuring and Cutting the Old Pipe

Mark the section of the old pipe where the new connection will be made. Use a pipe cutter for metal pipes or a fine-toothed handsaw for PVC to ensure a clean, square cut. Remove the cut-out segment if splicing into a line to add a wye or tee fitting.

- For drain lines, remove a segment about 1 to 2 inches longer than your new fitting to allow space for couplings.

- Allow excess water to drain out; use a towel to dry the ends thoroughly.

2. Cleaning and Smoothing Pipe Ends

Deburr and smooth the cut edges using a file or sandpaper, both inside and outside the pipe. For plastic pipes, remove all burrs to prevent material buildup and ensure proper glue adhesion. Metal pipes may need a wire brush for rust or corrosion removal.

3. Selecting the Right Fittings

Choose fittings that are compatible with both the old and new pipe materials. This is especially important when connecting dissimilar materials, such as PVC to cast iron or copper.

- Rubber transition couplings (with hose clamps): Good for joining PVC to cast iron or clay.

- SharkBite or push-fit fittings: Enable quick, tool-free connections between copper, PEX, or CPVC.

- Metal-to-plastic adaptors: Allow threaded connections between copper/steel and plastic pipes.

4. Dry Fitting and Test Assembly

Before applying glue or making permanent connections, dry-fit all components in place. Ensure all sections fit snugly, are aligned properly, and leave enough room for slip couplings or expansion.

5. Making the Connection

The exact steps vary depending on pipe materials. Below are the most common methods:

For PVC or ABS to Plastic Pipes

- Prime and Glue: Use a purple primer to clean and soften mating surfaces. Follow immediately with PVC/ABS solvent cement on both surfaces. Push the pipe fully into the fitting with a quarter-turn twist to spread adhesive evenly.

- Slip Couplings: For splicing into existing drains, slip couplings can be slid back to allow space for the new wye or tee. Then repositioned over the joints before the glue sets for a watertight seal.

For Copper or Metal to New Pipes

- Threaded Adapters: Use threaded metal adapters with Teflon tape on male threads before tightening into older pipes.

- Soldering: For copper connections, clean pipe ends, apply flux, and heat with a torch. Solder is drawn into the joint for a permanent bond.

- Push-Fit Connectors: Push-fit (SharkBite) fittings simplify connections, especially in tight spaces, and work across copper, PEX, and CPVC.

For Cast Iron or Other Older Materials

- Rubber Couplings: Use no-hub (Mission) rubber couplings with stainless steel bands to connect plastic drain sections to existing cast iron.

- Compression Fittings: When threading or soldering isn’t possible, compression fittings provide a leak-proof joint by tightening a gasket or ring.

Common Scenarios: Drain, Water, and Supply Lines

Because each aspect of a home’s plumbing serves a different purpose, techniques may differ:

| Line Type | Common Old Material | Common New Material | Recommended Joint |

|---|---|---|---|

| Drain (DWV) | Cast iron, clay | PVC, ABS | Rubber transition couplings |

| Water supply | Copper, galvanized | PEX, copper, CPVC | Push-fit connectors or threaded unions |

| Vents | Steel, cast iron | PVC | Plastic-to-metal adaptors and clamps |

Troubleshooting and Best Practices

- Work quickly, but precisely: Solvent-welded joints bond fast—pre-position couplings before applying glue.

- Align carefully: Any misalignment creates pressure on joints or weakens seals.

- Add supports: Use pipe straps or hangers to prevent sagging, especially for horizontal drains.

- Check for leaks: Once assembled, restore water and check all joints with a dry towel. Look for seepage or drips.

- Follow local codes: Plumbing codes may specify transition fittings or prohibit certain DIY connections; check before starting.

Common Mistakes to Avoid

- Skipping surface cleaning before gluing or soldering, which weakens joints.

- Using the wrong type of coupling or fitting for dissimilar materials.

- Failing to support or strap horizontal pipe runs, causing stress on new joints.

- Not checking for pitch (slope) on drain pipes, leading to slow drainage or backups.

- Over-tightening threaded connections, risking cracks in plastic fittings.

Helpful Tips for DIYers

- Always “dry-fit” pipes and fittings ahead of time to confirm layout and sizing before final assembly.

- Have all necessary tools, primers, and glues within arm’s reach before starting solvent-weld connections.

- Label or photograph complicated assemblies during disassembly for easier reassembly.

- Invest in a reciprocating saw or pipe cutter for neat, accurate pipe cuts, especially in tight spaces.

- When unsure, consult a licensed plumber, especially for main drains or high-pressure supply pipes.

Frequently Asked Questions (FAQs)

Q: Can I connect PVC drain pipes directly to old cast iron lines?

A: Yes, use a rubber transition (no-hub) coupling with stainless steel bands to join the two. Tighten firmly to prevent leaks and follow code requirements for transitions.

Q: What’s the best way to join copper water pipes to PEX?

A: Push-fit (SharkBite) connectors are excellent for joining copper to PEX quickly and securely, with no soldering required. Be sure to use an insert stiffener with PEX tubing.

Q: How do I prevent leaks at the new connection points?

A: Clean and dry all surfaces thoroughly, use quality primer and solvent/cement for plastic pipes, and don’t over-tighten. Test each joint when restoring water pressure or running a drain test.

Q: Do I need a permit to update or connect new plumbing lines?

A: Most local building codes require permits for significant plumbing changes, especially when connecting to main vent or drain lines. Always check with your municipal building department before starting.

Q: How do I reconnect pipes in tight or awkward spaces?

A: Use slip couplings for PVC, compression unions for metal pipes, or flexible transition fittings. Pipe cutters with rotating heads and compact push-fit connectors can also help where access is limited.

Safety Considerations

- Wear safety goggles and gloves, especially when cutting or soldering.

- Ensure proper ventilation if using solvent cements or soldering fluxes indoors.

- Dispose of cut-off pipe sections and unused chemicals according to local regulations.

- If working near electrical wiring, shut off circuits or call a professional for complex jobs.

Conclusion: Secure, Long-Lasting Connections

Successfully connecting new pipes to old plumbing lines requires careful preparation, the right materials, and sound technique. By following the methods outlined above, you can safely upgrade your home’s plumbing system—reducing the risk of leaks and ensuring decades of reliable performance. When in doubt, consult a licensed professional for guidance on complex or high-risk connections.

References

Read full bio of Sneha Tete