Thermal Bridges: The Hidden Culprit of Building Heat Loss

Understanding how poor design and thermal bridging can cause severe heat loss, increased energy bills, and building failures.

Thermal Bridges: The Silent Threat to Energy-Efficient Buildings

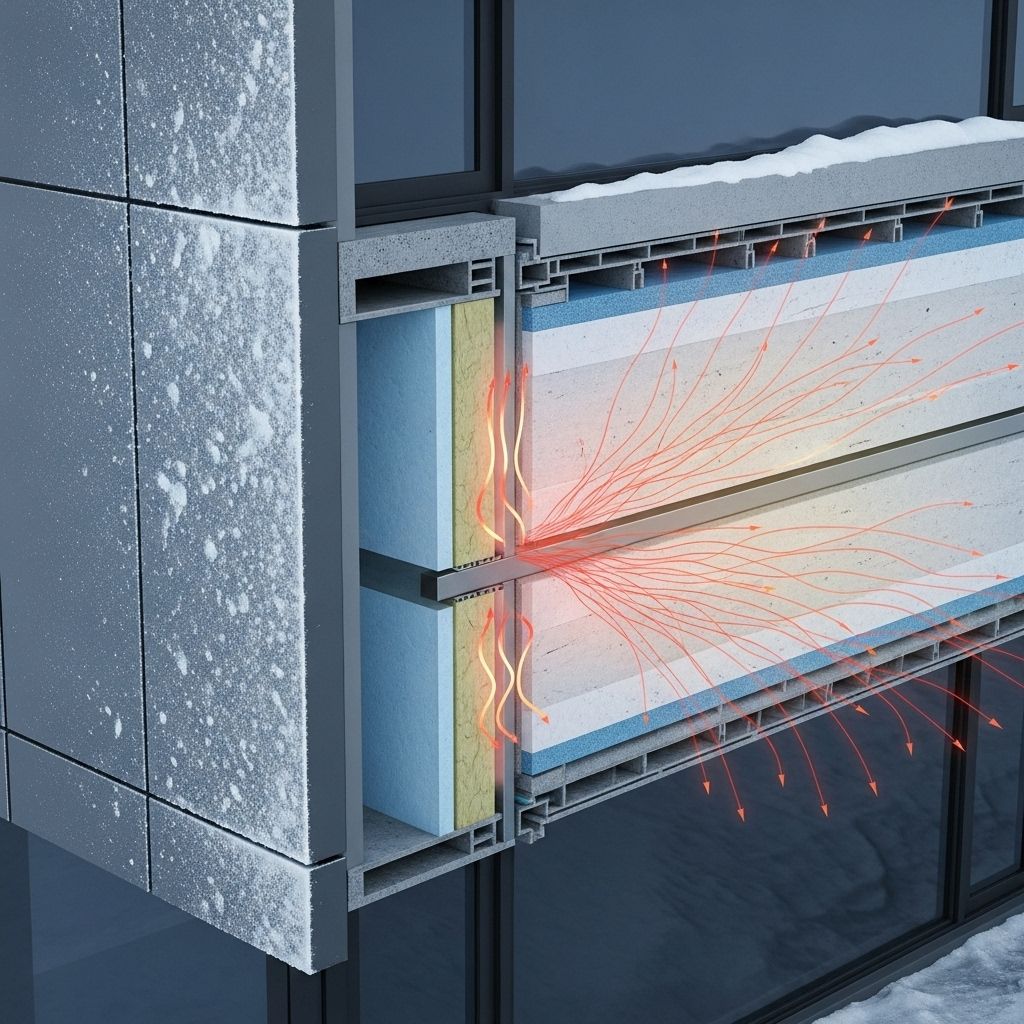

In the drive for greener, more sustainable buildings, one often-overlooked villain sabotages energy performance: thermal bridges. These sneaky pathways bypass insulation and funnel precious heat out of our homes and offices, hiking energy costs and threatening structural health. This article explores what thermal bridges are, why they are so damaging, and how thoughtful design can minimize their impact.

What Is a Thermal Bridge?

A thermal bridge occurs when a section of a building envelope—such as a wall, roof, or floor—allows heat to move through it more easily compared to adjacent, insulated areas. This typically happens where insulation is interrupted, penetrated by materials of higher thermal conductivity, or where building components connect in ways that create a direct path for heat flow.

- Common locations: Wall and floor junctions, window or door frames, balconies, penetrations for pipes or cables, and areas where steel or concrete passes through insulation.

- Alternative names: Cold bridge, thermal bypass, thermal break (when properly addressed).

Thermal bridges are more than a minor flaw—they can cause major increases in heat loss, undermine insulation, and encourage condensation and mold.

How Do Thermal Bridges Affect Heat Loss?

The science is straightforward: heat is always seeking equilibrium, moving from warmer interiors to the colder outdoors. In a well-insulated building, this migration is slowed everywhere except at thermal bridges, where it races through. The result is:

- Disproportionate heat loss: Even small thermal bridges can account for substantial percentages of total heat lost through the building envelope, sometimes exceeding 30% if left unaddressed.

- Cool interior surfaces: Lower surface temperatures near bridges increase condensation risk, leading to mold growth and possible structural deterioration.

- Higher energy bills: Extra heating is needed to compensate for the losses, raising running costs.

Why Insulation Alone Isn’t Enough

When walls or roofs are well-insulated, the relative impact of a single thermal bridge becomes more severe. With typical insulation, most areas have low heat flow, making the ‘short-cut’ of a bridge a more significant failure. This can lead to situations where adding insulation appears to make the bridge worse when measured by the thermal bridge coefficient (Ψ-value), even though overall heat loss is reduced.

Types of Thermal Bridges

Thermal bridges come in a few distinct categories, each requiring its own strategy to address:

- Geometric thermal bridges: Created by the shape or geometry of building features (e.g., external corners or junctions).

- Material thermal bridges: Occur where conductive materials (steel, concrete, masonry) break through the insulation barrier.

- Structural thermal bridges: Result from structural connections—such as balconies or floor slabs passing through to the exterior.

The Perimeter Problem: Foundations and Slabs

Slab-on-grade foundations—a common element in low-rise construction—are notorious for their susceptibility to thermal bridging at the junction of wall and slab. Research shows that heat loss at these junctions can be dramatically higher than assumed if thermal bridges are not well managed.

- Heat escapes through direct contact between foundation and the ground.

- Floor heating makes perimeter loss even more pronounced.

- International standards: Most modern codes now require thermal bridge effects to be included in whole-building heat loss calculations.

Why Are Thermal Bridges Often Overlooked?

Several factors contribute to the prevalence of thermal bridging, even in supposedly efficient buildings:

- Complex geometry: Three-dimensional intersections are hard to model and are often missed in two-dimensional design calculations.

- Poor detailing: Construction drawings may not specify continuous insulation or thermal breaks at key junctions.

- Cost-cutting: Builders may omit advanced materials or techniques that would properly disrupt bridges.

- Lack of awareness: Energy-conscious design focuses on insulation and airtightness but neglects the bridges that undermine both.

Calculating and Measuring Thermal Bridges

Effective management begins with accurate identification and quantification. There are standard procedures for calculating the added heat loss caused by a bridge:

- Step 1: Calculate heat flow through uninterrupted building component.

- Step 2: Model the actual (bridged) component in heat flow software.

- Step 3: Compute the thermal bridge coefficient Ψ (Psi-value), in W/(mK), which represents additional heat loss per meter due to the bridge.

Three-dimensional simulation methods are increasingly used, as they more accurately capture the complex paths heat can take through real intersections—much better than outdated two-dimensional models.

The Consequences: More Than Just Lost Heat

If unchecked, thermal bridges inflict damage far beyond wasted energy. They lower the temperature of internal surfaces, inviting condensation in winter. Over time, moisture can weaken materials, corrode metal, and fuel the growth of mold and mildew at cold spots.

| Problem | Cause | Possible Result |

|---|---|---|

| Condensation | Low surface temp at bridge | Mold, mildew, indoor air quality issues |

| Structural damage | Moisture, frost cycles | Metal corrosion, concrete spalling |

| Increased costs | Heat loss, higher bills | Carbon emissions, poor ROI on insulation |

Thermal Bridge-Free Design Principles

Sustainable buildings aim for thermal-bridge-free design, a core attribute of Passive House and high-performance standards. The central idea is to minimize or eliminate direct paths of heat flow through strategic detailing, advanced materials, and construction methods.

- Continuous insulation: Insulation that covers the building envelope with no gaps or penetrations.

- Thermal breaks: Insertion of materials with low thermal conductivity to disrupt heat flow (e.g., plastic, foam composites).

- Advanced framing: Design that reduces contact between conductive elements and the exterior.

- High-performance fenestration: Window and door designs that include insulated frames and spacers.

Thermal Breaks: The Cure for Thermal Bridging

A thermal break is a deliberate interruption in the continuity of a conductive material, created by introducing a barrier with low thermal conductivity. For example:

- Balcony connections: Use of special pads or composites between slab and wall to block heat escape.

- Steel frame penetrations: Non-metallic spacers disrupt flow from internal to external steel.

- Window frames: Insulating foams or plastics separate the conductive window components from the envelope.

The concept is like the insulated handle of a metal pot—preventing your hand from getting burned while the pot cooks your food.

Materials and Technology Solutions

With the rise in awareness of building envelope performance, manufacturers have developed high-tech solutions. Thermal break products now offer low conductivity with high compressive strength, making them suitable for use in:

- Wall assemblies

- Roof-to-wall and floor-to-wall connections

- Structural penetrations for decks and balconies

These materials are tested and modeled in three dimensions, ensuring they provide real-world improvements in both heat loss and condensation control.

Regulations and Compliance

Throughout the world, energy standards now require designers to address thermal bridging. In Europe, advanced energy rating systems include thermal bridge effects, and building regulations (such as the UK’s Part L) demand adequate details to prove compliance. Leading codes specify:

- Continuous insulation and breaks at key junctions

- Verified thermal performance using simulation tools

- Demonstration of interior surface temperatures above mold-risk thresholds

Case Study: Accredited Construction Details

Governments and industry bodies provide catalogs of Accredited Construction Details (ACDs) for thermal bridge management. These standardized solutions help ensure compliance and effective energy performance—if properly followed.

Real-World Examples: Thermal Bridging in Action

Thermal bridging is visible in many common building problems:

- Frosty corners: Internal corners colder than adjacent walls, often with peeling paint or mold.

- Balconies: Slabs jutting out from insulated walls form direct heat paths, sometimes causing ice or damp at interior junctions.

- Window frames: Poorly insulated frames create cold spots, evidenced by condensation on glass edges.

Design failures from the 20th century often show these effects, but they persist today in new buildings when details are overlooked.

Minimizing Thermal Bridges: Best Practices

- Design for continuity: Always ensure insulation wraps around junctions and penetrations.

- Use proven products: Specify materials and components with tested low-conductivity properties.

- Model in three dimensions: Employ software that simulates full heat flow paths at complex intersections.

- Check Accredited Details: Refer to government or industry details that have been certified for performance.

- Educate builders and designers: Share knowledge about bridging risks and prevention strategies.

Frequently Asked Questions (FAQ)

Q: Can a thermal bridge cause structural damage?

Yes, over time repeated condensation at cold spots can corrode metal ties, spall concrete, and degrade building materials, leading to repair costs and reduced lifespan.

Q: Is it possible to eliminate all thermal bridges?

No building can be 100% free of thermal bridging. The goal is to minimize them so the total heat loss is no greater than that of the rest of the envelope and surface temperatures stay above critical levels for mold prevention.

Q: Why do well-insulated buildings sometimes have worse Ψ-values?

This is a function of how the thermal bridge coefficient is calculated: the relative additional loss compared to the undisturbed area. When wall insulation makes most of the envelope very good, even a small bridge looks worse in relative terms, but overall heat loss is reduced.

Q: What materials can be used as thermal breaks?

Typical choices include plastics, composite foams, and specialized low-conductivity pads designed for high-strength applications.

Conclusion: Designing Out Thermal Bridges

Thermal bridging is a hidden but powerful source of heat loss, damaging both building performance and occupant comfort. As codes tighten and energy costs rise, understanding and delivering thermal-bridge-free design becomes essential for all architects, engineers, and builders. With advanced materials, careful detailing, and informed construction, buildings can keep the heat inside and the cold outside—where it belongs.

References

- https://web.ornl.gov/sci/buildings/conf-archive/2007%20B10%20papers/222_Roots.pdf

- https://blog.passivehouse-international.org/what-is-a-thermal-bridge/

- https://passivehouseaccelerator.com/articles/six-things-to-know-about-thermal-bridging

- https://www.armatherm.com/wp-content/uploads/2024/06/Armatherm-Thermal-Bridging-Solutions-Vol-2.pdf

- https://stroma.com/latest-news/thermal-bridging-explained-improving-building-performance-with-acds/

- https://www.h2xengineering.com/blogs/understanding-thermal-bridging-impact-building-heat-loss/

- https://passipedia.org/basics/building_physics_-_basics/what_defines_thermal_bridge_free_design

- https://www.kingspan.com/gb/en/knowledge-articles/what-is-thermal-bridging/

- https://www.structuremag.org/article/structural-thermal-bridging-in-buildings-part-1-structural-penetrations/

- https://www.facadetectonics.org/articles/thermal-bridging-the-missing-key-to-low-energy-building-design

Read full bio of Sneha Tete