Beyond Concrete: Rethinking the Future of Building Materials

As the environmental toll of concrete becomes undeniable, a new era of sustainable building materials is on the horizon.

Concrete stands as the literal foundation of contemporary civilization, used in everything from homes and highways to skyscrapers and seaports. Yet, as the climate crisis accelerates, scrutiny has intensified around concrete’s carbon footprint and environmental impact. Pressure is building to replace, reduce, or radically reform one of history’s most ubiquitous and destructive construction materials.

Why Rethink Concrete?

The global reliance on Portland cement–based concrete produces staggering consequences for the environment:

- Massive CO2 Emissions: Concrete production is responsible for approximately 7–8% of all global greenhouse gas emissions, largely from the calcination process that produces cement clinker and the energy used to heat kilns.

- Resource Intensity: Concrete manufacturing consumes immense amounts of natural aggregates, sand, and water, putting severe pressures on regional ecosystems.

- Urban Impacts: Concrete surfaces amplify urban heat islands, disrupt groundwater recharge, drive runoff and flooding, and contribute to local air and noise pollution.

The environmental price cannot be ignored any longer. For a climate-resilient future, a transformation in our approach to construction materials is imperative.

The Challenge: Structural and Cultural Inertia

Despite the environmental imperatives, concrete thrives for a host of practical reasons:

- Ubiquity and Familiarity: Builders, engineers, and regulators worldwide are accustomed to its predictable performance, fast curing, and code compliance.

- Cost: Concrete remains relatively cheap when externalities like carbon or water scarcity are not priced into the system.

- Durability: Properly made and maintained, concrete structures can last for decades or centuries.

These advantages have entrenched concrete as the de facto choice for infrastructure – even as its shortcomings grow harder to ignore.

Concrete’s Heavy Environmental Toll

Understanding the full spectrum of concrete’s environmental harm is crucial in motivating change:

- CO2 from Cement: Most emissions come from the transformation of limestone (CaCO3) into lime (CaO), releasing CO2 in the process, and from energy-intensive kiln operations.

- Water Demand: Concrete production accounts for nearly 10% of global industrial water use. By 2050, most water needed for concrete production will occur in regions likely to suffer significant drought.

- Land Disruption: Mining sand and aggregates damages riverbeds and landscapes, causing erosion and habitat loss.

- Urban Runoff: Hard, impermeable surfaces cause flooding and pollution, impacting cities worldwide.

Given concrete’s legacy, numerous pathways now compete to address its negative impacts, whether through incremental reforms or outright alternatives.

The Search for Greener Concrete

1. Reformulating Concrete: Lower-Carbon and Recycled Blends

- Supplementary Cementitious Materials (SCMs):

- Fly Ash and Slag: By-products from coal power and steelmaking, used to partially replace Portland cement, lowering emissions.

- Challenges: Supply constraints (especially for fly ash, as coal use declines), and regulatory caution around unproven blends.

- Green Concrete Startups: Companies such as Ceratech create cements with up to 95% fly ash, and projects like the I-35W Saint Anthony Falls Bridge innovate with variable mixes for performance and emissions reductions.

- Carbon Capture in Concrete:

- CarbonCure: Injects captured CO2 during mixing, sequestering it in mineral form.

- Blue Planet: Converts captured carbon into synthetic aggregate for use in concrete.

- Electrochemical and No-Kiln Methods: Emerging processes, such as those by Sublime Systems and Fortera, bypass fossil-fueled kilns using renewable electricity to drastically cut emissions.

2. Recycling Concrete: Towards a Circular Model

- Crushed Concrete as Aggregate: Old concrete structures are demolished, and the rubble is processed into new aggregate, closing the material loop and saving on resources.

- Zero Carbon Cement:

- Cambridge Electric Cement: Pioneered at Cambridge University, this method integrates steel and cement recycling in electric arc furnaces, producing new cement clinker from processed slag and recycled concrete – powered by renewables for nearly zero emissions.

- Limitations: Scaling is an issue, as there are not enough demolished buildings or steel-industry slag to meet global cement demand.

The Promise and Perils of Concrete Alternatives

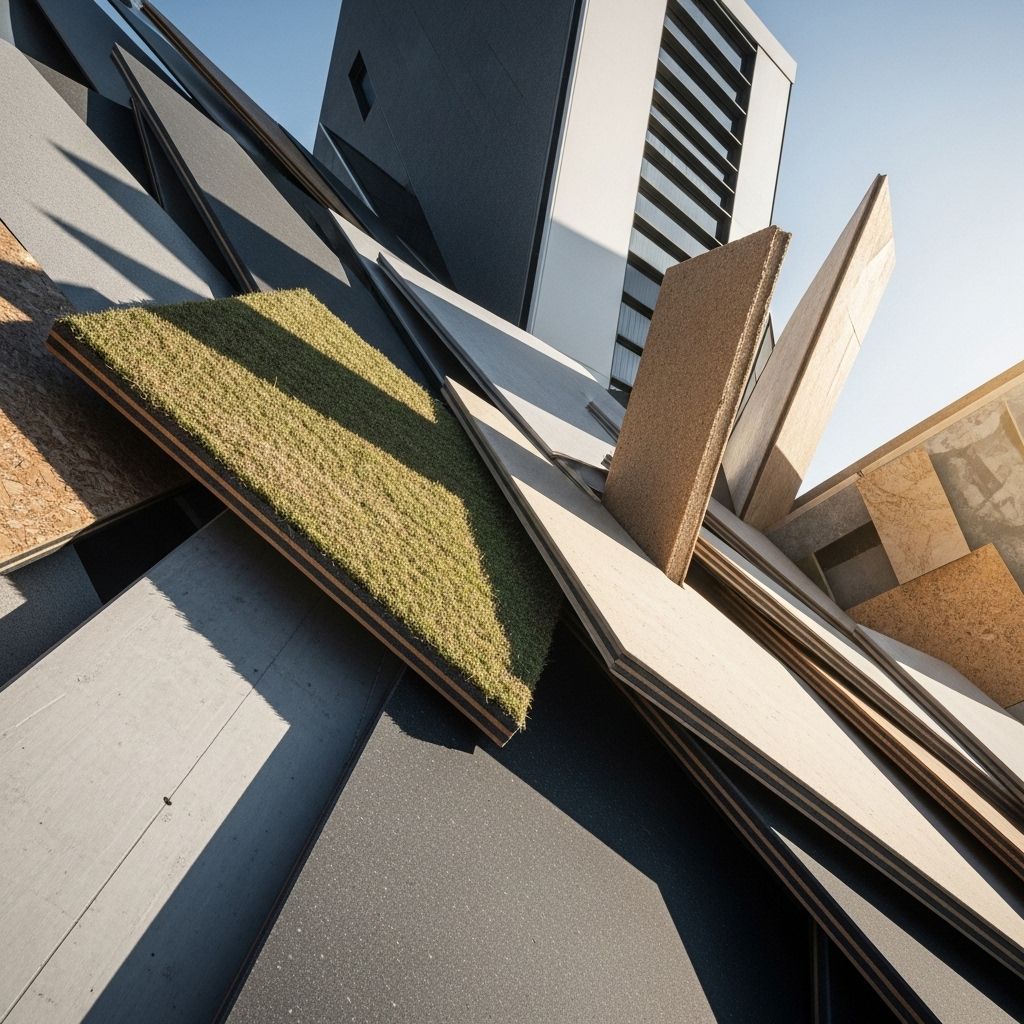

For a true paradigm shift, the industry is exploring beyond incremental reform to radically different building materials.

1. AirCrete: The Lightweight, Insulating Block

- What is AirCrete?

- Composition: A foamed mixture using cement, water, and a foaming agent to create a strong but lightweight-building block filled with small air bubbles.

- Benefits:

- High insulation value (R-value of 6 per inch vs. 0.1–0.2 for regular concrete).

- Low cost and use of cement (10x cheaper than traditional construction for single-story homes), reducing emissions and resources.

- Fireproof, water-resistant, insect-resistant, easy to shape with woodworking tools, and fast to cure.

- Ideal Uses: Owner-built, affordable homes; simple dome structures; areas needing high insulation.

- Limitations: Less structural strength; best for non-load-bearing walls or combination with stronger frameworks.

2. Clay and Earth-Based Construction

- Ancient Roots, Modern Applications

- Earth Buildings: Adobe, rammed earth, and cob structures have been used for millennia and are being revived, sometimes in combination with contemporary engineering.

- 3D Printed Clay Homes: Projects like Tecla utilize local soil with binders and natural fibers to create affordable, climate-adaptive homes with strong insulation, low waste, and very minimal emissions.

- Benefits: Extremely low embodied carbon, customizable forms, local material sourcing, quick fabrication, low-cost and little specialized labor.

- Limitations: Geography-specific (relies on suitable local soil), may face regulatory and durability challenges in some climates.

3. Timber, Mass Timber, and Engineered Wood

- Timber Renaissance

- Mass Timber: Laminated beams and panels made from fast-growing managed forests can rival steel and concrete in structural roles while sequestering carbon.

- Benefits: Renewable, locks away CO2, typically less energy-intensive than concrete or steel to produce.

- Limitations: Requires sustainable forestry, may not always be suitable for all load-bearing or fire/exposure requirements.

4. Unconventional Green Mixes and Innovations

- Ashcrete: Blend of lime and ash, leveraging waste byproducts and lowering emissions.

- Black Furnace Slag Concrete: Repurposes molten iron slag with water to create binders.

- Papercrete and Glass-Composite Cement: Incorporate waste paper and post-consumer glass into cementitious matrices for bespoke applications.

- Bio-Based Binders: Agricultural byproducts, algae, and fungi are generating research interest as alternative, low-energy binders.

Barriers to Change: Why Concrete Persists

Despite the rising promise of alternatives, barriers to radical change persist:

- Regulatory Reluctance: Most codes and safety standards are written for conventional mixes, discouraging risk-taking.

- Lack of Long-Term Data: Construction’s conservatism stems partly from untested lifespans and unpredictable performance of new materials.

- Scale: The world builds trillions of tons of concrete annually; even promising alternatives often meet only niche demand or pilot projects.

- Economic Incentives: In the absence of carbon taxes or environmental regulation, greener options can be costlier up front, dampening adoption.

Strategies for a Concrete Transition

While no single replacement can match concrete’s universality and capabilities, a range of complementary strategies is emerging:

- Material Efficiency and Design Innovation: Reducing cement content through smarter design, longer spans, and lighter structures.

- Integrating Recycling Loops: Rethinking demolition and end-of-life to view concrete as a reusable resource, not waste.

- Diversifying Material Choices: Encouraging region-specific approaches: mass timber in well-forested zones, earth/clay where suitable soils exist, and low-carbon cements in high-rise or infrastructure roles.

- Policy and Codes: Reforming standards to allow safe experimentation and gradual mainstreaming of alternatives, supported by subsidies, R&D, and carbon pricing.

Challenges Ahead

No single solution will eradicate concrete’s carbon burden overnight. However, a blend of policy, design innovation, and material science can steer construction towards a climate-friendly future. The complexity is daunting, but the stakes – the planet’s climate stability and future habitability – demand an ambitious, concrete plan for change.

Frequently Asked Questions (FAQs)

Q: Is it possible to completely replace concrete in construction?

A: Completely replacing concrete everywhere is unlikely for now. However, many projects can use alternatives or blends that dramatically reduce emissions and improve sustainability, especially in low-rise, residential, or non-structural applications.

Q: Which alternative material is most promising for large-scale construction?

A: Currently, no alternative matches concrete’s full performance profile at scale. Low-carbon cements, recycled content, and mass timber show the greatest potential for mainstreaming in sizable structures.

Q: What are the major obstacles to adopting greener concrete alternatives?

A: Regulatory codes written for conventional mixes, lack of proven long-term durability data, economic disadvantages without carbon pricing, and resistance to change within the industry.

Q: How can individuals or small builders make a difference?

A: By choosing greener materials (like AirCrete, straw bale, or recycled masonry), reducing the amount of new concrete, advocating for better policies, and demanding material transparency, even small-scale builders can influence broader trends.

Q: Will concrete’s environmental footprint improve significantly soon?

A: Progress is happening, especially as startups bring new approaches to market and some large projects adopt lower-carbon mixes. Yet, rapid transformation depends on supportive policy frameworks, investment in R&D, and cultural shifts in construction.

References

- https://goldenreblog.com/tag/concrete-homes/

- https://www.natureworldnews.com/articles/51112/20220531/zero-carbon-cement-recycled.htm

- https://en.wikipedia.org/wiki/Environmental_impact_of_concrete

- https://givingcompass.org/article/mass-timber-construction-is-about-more-than-just-storing-carbon

- https://www.designboom.com/architecture/modus-architects-treehugger-tourist-office-italy-02-06-2020/

- https://home.howstuffworks.com/home-improvement/construction/green/10-alternative-housing-ideas.htm

Read full bio of medha deb