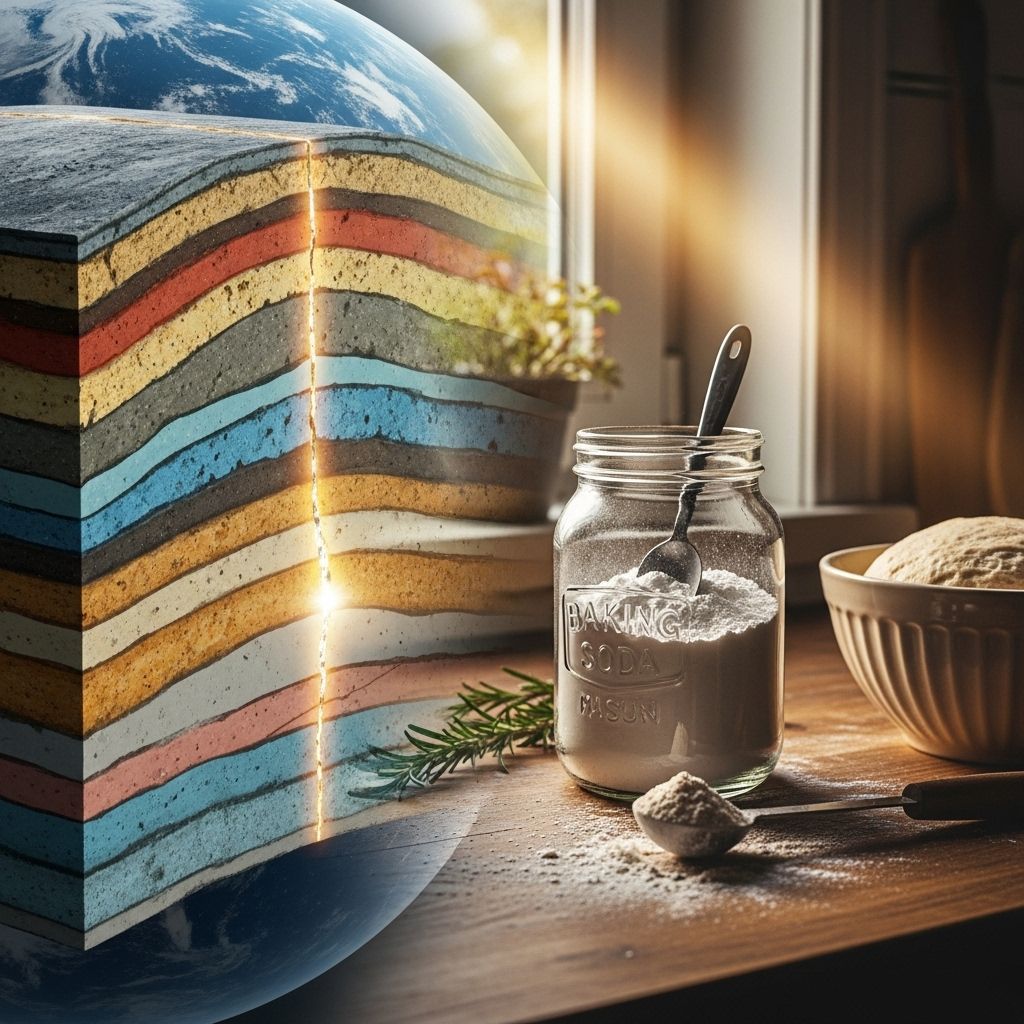

The Origins and Journey of Baking Soda: From Earth to Kitchen

Tracing baking soda from its natural roots and complex manufacturing, to its central role in eco-friendly living across the globe.

Where Does Baking Soda Really Come From?

Baking soda, or sodium bicarbonate (NaHCO3), occupies a special place in modern households. It’s lauded for its versatility—used for baking, cleaning, deodorizing, and even as a mild medicine. But few ever pause to consider: where does this trusted white powder actually originate? By tracing the baking soda supply chain, from natural mineral to your kitchen shelf, we unlock insightful perspectives about its production, environmental toll, and surprising history.

The Primary Source: Where It All Begins

The majority of the world’s baking soda comes from trona ore—a mineral rich in sodium carbonate—that forms deep underground, particularly in arid, ancient lakebeds. The world’s largest natural trona reserves lie in Wyoming’s Green River Basin, USA, which supplies roughly 90% of American sodium carbonate and a significant share of global demand. Trona beds were deposited in this region over 50 million years ago as primeval lakes slowly evaporated, leaving behind vast mineral layers.

- Trona mining is essentially the “beginning” of commercial baking soda production.

- Other sources include rare naturally occurring baking soda deposits (natron), notably in dry lake beds in Egypt and Africa, but these are not significant in global production today.

How Baking Soda Is Mined and Processed

Baking soda never arrives on supermarket shelves straight from the earth: the journey from raw trona ore to the pureness demanded by food and pharma industries requires multiple steps of engineering and care. Let’s break down this complex transformation.

Mining Trona: Two Critical Approaches

- Conventional Underground Mining: Trona deposits are extracted using deep shaft mining, much like coal. Tunnel networks up to a thousand feet underground access vast beds of trona ore, which is mechanically extracted and brought to the surface.

- Solution Mining: In some places, heated water (and sometimes chemicals) are injected into trona beds to dissolve the mineral. The resulting brine is then pumped up and processed at surface plants.

Each approach has its own energy requirements, technical challenges, and environmental considerations. Underground mining is resource-intensive, requiring slurry pumps, powerful ventilation systems, and many safety precautions. Solution mining, while sometimes less labor-intensive, can involve large quantities of heated water and increases risk of groundwater contamination if improperly managed.

From Trona to Soda Ash

After mining, trona ore undergoes a series of processes to separate impurities and extract soda ash (sodium carbonate). Key steps include:

- Crushing and Calcining: Trona is crushed, then heated in rotary kilns. This decomposes it into soda ash, water vapor, and carbon dioxide.

- Dissolution and Purification: The soda ash is dissolved in water, filtered to remove insolubles, and sometimes chemically clarified for extra purity.

The Solvay Process: Synthetic Production of Baking Soda

While natural trona is the dominant source in North America, much of the world’s sodium bicarbonate is synthesized using the legendary Solvay process. Developed in the mid-19th century, the Solvay process revolutionized base chemical manufacturing and remains a linchpin of modern industrial chemistry.

The Solvay process involves several steps:

- Preparation of Brine: Pure sodium chloride (NaCl)—table salt—is dissolved in water.

- Ammonia Introduction: Ammonia (NH3) gas is bubbled through the brine.

- Carbon Dioxide Addition: Carbon dioxide (CO2) is generated by heating limestone (CaCO3), then introduced into the solution.

- Formation of Sodium Bicarbonate: The reaction between brine, ammonia, and CO2 produces sodium bicarbonate (baking soda) and ammonium chloride as a byproduct.

- Separation and Drying: Baking soda is less soluble and precipitates out. It is filtered, washed, and dried to reach commercial quality.

Today, the Solvay process is especially important in parts of the world without large natural trona reserves, providing a steady and high-volume supply of crucial industrial chemicals.

Final Purification and Packaging

Before baking soda is ready for shelves, it undergoes additional refinement:

- Crystal Washing: The separated sodium bicarbonate crystals are washed to remove residual salts and impurities.

- Drying: The purified crystals are carefully dried, often using vacuum chambers for energy efficiency, ensuring they are free-flowing and moisture-free.

- Milling and Anti-Caking: Final baking soda crystals are milled into fine powders. For food and healthcare use, an anti-caking agent may be added to prevent clumping.

- Packing: The finished product is dispatched into boxes or plastic containers under highly controlled conditions that maintain purity and safety.

Global Production and Environmental Impact

Baking soda might seem like a humble product, but its production is vast in scale and comes with environmental implications. Here’s what conscious consumers should know:

Environmental Costs of Trona Mining

- Land Disruption: Both underground and solution mining disturb large tracts of land, with issues ranging from habitat loss to soil instability.

- Water Use: Solution mining is water-intensive, and improper management can pose risks to local water tables.

- Air Emissions: Calcining trona and processing soda ash both release carbon dioxide, contributing to greenhouse gas output, though trona-based methods are more energy-efficient than synthetic alternatives overall.

Solvay Process: Challenges and Progress

- Ammonia Recovery: One of the Solvay process’s strengths is its near-complete recycling of ammonia, reducing chemical input costs and emissions.

- Byproduct Concerns: Ammonium chloride produced as a byproduct is often reused in fertilizer manufacturing, helping close the loop on industrial waste where possible.

- Water Pollution: Historical Solvay plants sometimes released chloride-rich wastewater, but tighter regulations have spurred cleaner production and improved waste management in most modern plants.

Sustainable Choices and Innovations

- Wyoming’s trona operations trump Solvay plants for overall energy and carbon efficiency.

- Modern mining emphasizes land restoration and water reuse to reduce long-term damage.

- Consumers can look for baking soda labeled “mined from natural trona ore” if regional, ecological impact is a selection criterion.

Versatility: Baking Soda’s Many Roles

Baking soda is famous for being the original multi-tasker in the home. Its chemistry underpins its extraordinary range of uses:

- Baking Leavener: Forms carbon dioxide bubbles when exposed to acid and/or heat, raising doughs and batters.

- Odor Neutralizer: Absorbs acidic and basic odors, making it invaluable in refrigerators and cleaning routines.

- Mild Abrasive: Its crystalline structure makes it effective for gentle cleaning without scratching most surfaces.

- Fire Suppressant: Decomposes to release CO2, helping smother small grease fires.

- Medicinal: Used as an antacid for heartburn and as a mild antiseptic in oral care.

- Natural Cleaner: Eco-friendly, nontoxic, and biodegradable when disposed of properly.

Baking Soda vs. Soda Ash: What’s the Difference?

| Aspect | Baking Soda (Sodium Bicarbonate) | Soda Ash (Sodium Carbonate) |

|---|---|---|

| Chemical Formula | NaHCO3 | Na2CO3 |

| Uses | Baking, cleaning, deodorizing, medicinal | Water softening, glass, soap, detergent, paper production |

| Production | Mined from trona or synthesized via Solvay process | Primarily from trona or Solvay process (main output) |

| Household Prevalence | Very common | Uncommon in pure form for households |

Why Baking Soda Is a Green Cleaning Superstar

The *non-toxic*, highly effective, and versatile nature of baking soda means that for many eco-minded households it is a chosen alternative to harsh chemicals. Its easy biodegradability means that any run-off poses minimal threat compared to detergent-laden cleaners.

Baking soda’s neutrality in both production and disposal—especially when trona-based—makes it a star in green living, provided mining and manufacturing are managed responsibly. It is one of those rare bulk industrial chemicals that, under the right conditions, is as close to sustainable as mass chemical production gets.

Frequently Asked Questions About Baking Soda

Is all baking soda natural?

No. While much of the baking soda available in North America is derived from natural trona ore—especially if labeled as ‘mined’—most baking soda worldwide is produced synthetically via the Solvay process using salt and limestone.

Is baking soda production bad for the environment?

Baking soda is far gentler on the earth than many other industrial chemicals, especially when sourced from responsibly managed trona mining operations. The main environmental costs are from energy use in mining and calcination, along with potential land and water impacts without proper oversight. The Solvay process, while vital globally, uses more energy than mining natural trona reserves but has improved its waste management substantially over the past century.

Does baking soda ever expire?

Baking soda is highly stable and retains its potency for long periods if kept airtight and dry. Over time, especially if exposed to humidity, it may lose effectiveness as a leavening agent, but this usually takes years rather than months.

Can baking soda be replaced with baking powder?

Not directly. Baking powder contains both an acid and a base, so it can leaven baked goods alone, while baking soda requires an acid in the dough or batter to react. While both can be used as leaveners, their chemistry and effects in recipes are not interchangeable without careful adjustments.

What about health and safety risks?

Baking soda is non-toxic at regular doses but should not be consumed in excess. Excessive ingestion can cause metabolic alkalosis or sodium overload. As a cleaner or deodorizer, baking soda poses no significant safety risks in the home.

Conclusion: From Ancient Lakes to Modern Homes

Baking soda’s journey—from fossilized lakebeds or salt brines, through the intricate steps of mining, processing and purification, to your pantry—is a remarkable story of geology and chemistry. Respect for its source and sustainable use, both in industry and around the home, can help ensure this everyday marvel remains both accessible and gentle on our shared environment.

References

- https://www.echemi.com/cms/499728.html

- https://www.chemicalbook.com/article/the-manufacturing-process-and-uses-of-baking-soda.htm

- https://www.youtube.com/watch?v=6GofB0f6ztY

- https://www.youtube.com/watch?v=IEa65KeohS8

- https://en.wikipedia.org/wiki/Sodium_bicarbonate

- https://byjus.com/chemistry/preparation-properties-and-uses-baking-soda/

- https://patents.google.com/patent/US8865095B2/en

Read full bio of Sneha Tete