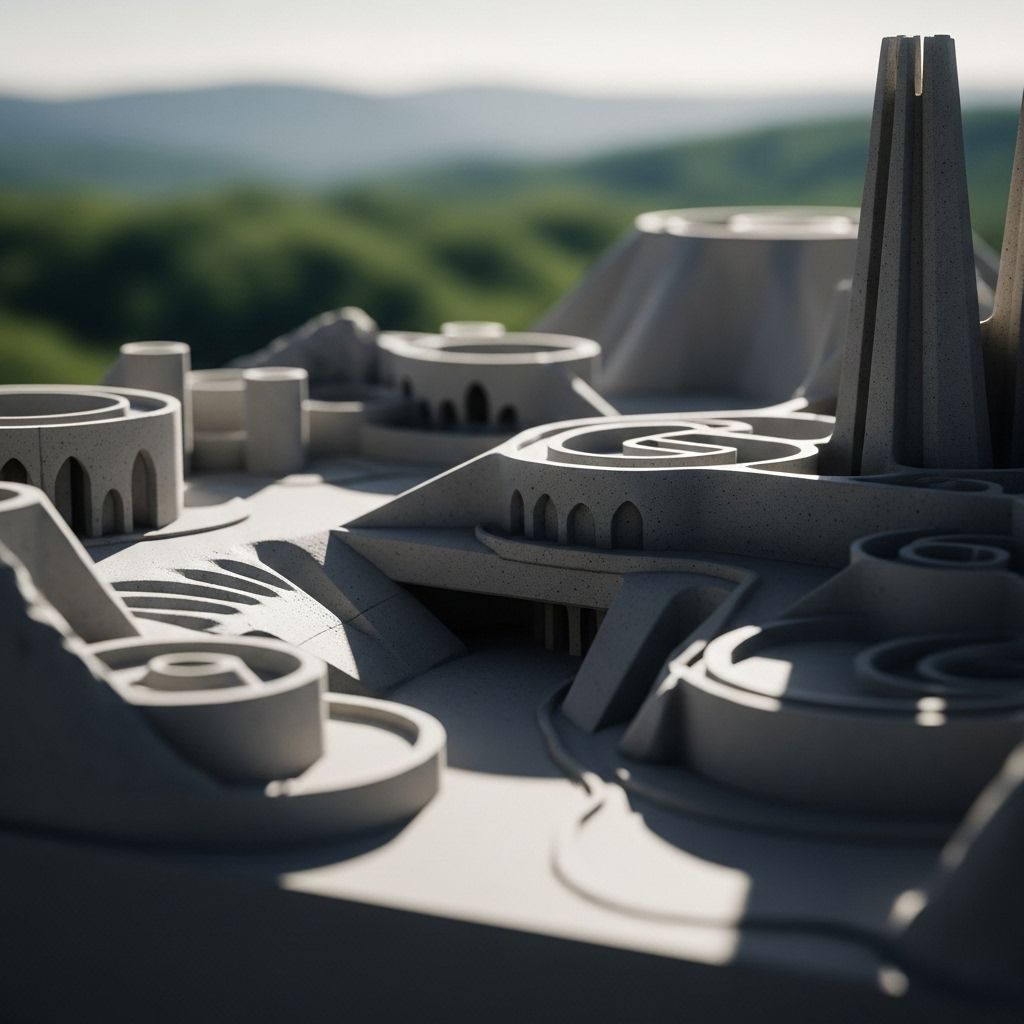

MiniMass: 3D-Printed Concrete for Ultra-Low Carbon Construction

MiniMass redefines structural engineering with 3D-printed concrete elements, slashing material use and carbon emissions while enabling bespoke, scalable design.

MiniMass: Rethinking Concrete Construction for the 21st Century

The construction sector faces urgent calls for transformation as it accounts for a large share of global carbon emissions and consistently struggles with stagnant productivity. Enter MiniMass—a groundbreaking family of 3D-printed, prefabricated concrete beams, frames, and slabs that promise to slash both embodied carbon and material costs, offering a scalable, structurally sound solution for sustainable development.

The Construction Industry’s Carbon Problem

Globally, the construction industry produces about 11% of total greenhouse gas emissions, a figure that rises to 39% when the entire built environment, including building operation, is considered. The path to a net-zero construction sector by 2050 requires at least a 25% emission reduction by 2030, primarily through efficient material use and decarbonization strategies. Concrete, a cornerstone of modern structures, is one of the primary contributors to this footprint.

The Promise of 3D Printing in Structural Concrete

3D printing—also known as additive manufacturing—has emerged as a key technology for reshaping the world of construction. Unlike traditional techniques that often lead to material overuse and unique element constraints, 3D printing allows for the precise, customizable creation of load-bearing elements on demand. This unlocks a suite of sustainability and productivity benefits:

- Material Efficiency: Reduce waste through optimized shapes and exact placement of material.

- Customization: Mass-customization is possible, allowing bespoke elements for each building without added cost.

- Labor Reduction: Automated fabrication means lower labor requirements and consistent quality.

What Sets MiniMass Apart?

MiniMass is not just a novel beam; it is an entirely new philosophy in structural engineering. By rethinking the way concrete and steel are used, it enables designers and builders to:

- Cut the embodied carbon in beams by up to 70% compared to conventional precast or in-situ concrete structures.

- Reduce material costs by roughly 20–50% for structurally equivalent performance.

- Deliver significant savings today, rather than waiting for long-term promises of low-carbon cements or exotic materials.

How It Works: The Logic of MiniMass Design

MiniMass beams are inspired by time-honored truss structures, but updated for the digital and decarbonizing age. The secret lies in optimizing the geometry and load paths so that:

- Top chord and web elements handle compression.

- Bottom chord handles tension.

The design leverages graphic statics, a method that visualizes and solves structural forces with geometry, ensuring each material is placed only where its properties are needed most. In doing so, MiniMass avoids pouring concrete in areas that do little work, reducing both mass and steel usage.

| Feature | Traditional Beams | MiniMass Beams |

|---|---|---|

| Material Used | High (solid sections) | Low (optimized truss form, hollow where possible) |

| Steel Reinforcement | Extensive | Minimal (sometimes none) |

| Embodied Carbon | High | Up to 70% lower |

| Customization | Standardized shapes, costly molds | Bespoke shapes at low marginal cost |

| Production Method | Precast or poured-in-place | Automated 3D printing, no formwork |

From Theory to Practice: Testing and Prototypes

The MiniMass concept has moved beyond computer modeling. Physical prototypes have been fabricated and subjected to large-scale load testing at the Technical University of Denmark (DTU), demonstrating that MiniMass can achieve the necessary bending and shear capacity for real-world structural applications. These prototypes exhibited load capacities comparable to—if not exceeding—those of similar traditional beams, but with a fraction of the material and environmental cost.

Patents and Technical Validation

- MiniMass beams are protected by multiple patents in the UK, US, and EU, for both the novel truss geometry and the manufacturing method.

- Their design is validated using established codes such as Eurocode 2 and ACI 318, providing confidence that engineers can safely integrate MiniMass elements into conventional building systems.

Benefits of MiniMass Technology

- No formwork required: Eliminates costly, waste-producing molds while enabling geometries impossible in traditional casting.

- Minimal steel reinforcement: By maximizing the areas in compression, less steel is needed compared to typical reinforced concrete.

- Reduced labor and construction cost: Automated printing means fewer hands on site and faster assembly.

- Mass customisation: Each beam, frame, or slab can be uniquely tailored without additional expense.

- Infinite scalability: From a single custom beam to thousands, the same process works at any quantity.

MiniMass Geometry and Structural Function

MiniMass beams visually resemble traditional trusses, with a network of ‘webs’ connecting top and bottom chords. This architecture is not mere aesthetics—it ensures:

- Even distribution of loads along optimized force paths

- Material only where needed, lowering total weight and volume

- Potential for unreinforced concrete, since the geometry encourages compression—concrete’s strong suit—instead of tension or bending, where concrete is weak

This structural logic borrows from the celebrated bridges of the 19th and early 20th centuries, now reimagined for 21st-century sustainability goals.

Managing Torsion: Current Limits and Development

- MiniMass beams, with their truss-like form, have lower torsional resistance than traditional solid beams. They require top flange restraint from the floor slab and temporary support during construction.

- A torsion-resistant version is under active development to address more demanding applications.

Integration with Evolving Materials and Methods

Although MiniMass currently uses conventional concrete and steel, it is designed to flexibly adopt new lower-carbon cements and advanced materials as they become viable. The process is compatible with:

- Ultra-high-performance concretes

- Recycled aggregate cement blends

- Other sustainable composites under research

If large numbers of identical elements are needed, traditional pre-casting methods can also be used—though 3D printing unlocks the maximum in design freedom and material efficiency.

MiniMass and the Path to Net Zero

The arrival of MiniMass offers a tangible pathway for the construction industry to markedly reduce its carbon footprint right now, years ahead of global net zero targets. By focusing on:

- Putting material only where it is structurally needed

- Dramatically reducing waste and emissions at the component level

- Leveraging digital fabrication for mass-customized construction

MiniMass delivers quantifiable progress toward the 25% emissions reduction goal for 2030, and positions building professionals to achieve net zero carbon structures by 2050.

Comparative Impact: MiniMass vs. Conventional Approaches

| Metric | Conventional Concrete Beam | MiniMass Beam |

|---|---|---|

| Embodied Carbon Reduction | – | 50–78% |

| Material (Concrete & Steel) Cost | Baseline | 20–40% lower |

| Customization Cost | High (unique molds) | Low (digital fabrication) |

| Formwork Requirement | Mandatory | None |

Looking Ahead: Challenges and Opportunities

- Adoption: The construction industry is often slow to adopt new technologies due to risk aversion; engineering validation and code compliance are vital for widespread acceptance.

- Materials Innovation: As 3D-printer-compatible, low-carbon cements mature, MiniMass beams will become even more sustainable and cost-effective.

- On-Site vs. Factory Production: MiniMass can be produced off-site (factory 3D printing) or potentially on-site in the future with mobile printing units—opening the door for modular and remote construction applications.

MiniMass: Frequently Asked Questions (FAQs)

Q: What are MiniMass beams made of?

A: Currently, standard concrete and steel are used, but the design is flexible for future low-carbon or recycled materials.

Q: How do MiniMass beams achieve such significant material savings?

A: The patented truss geometry places concrete only along force paths, eliminating unnecessary mass and minimizing steel by maximizing compression zones.

Q: Are MiniMass beams as strong as conventional beams?

A: Yes, load testing and calculations to recognized standards demonstrate equivalent or better bending and shear performance where properly applied.

Q: Can MiniMass beams be used in all building types?

A: While suited to many applications, the current design has lower resistance to torsion, meaning additional restraint or a torsion-resistant variant is needed for some projects.

Q: Is 3D printing required to make MiniMass beams?

A: No, though 3D printing maximizes customization and efficiency, large batches can be pre-cast conventionally if needed.

Conclusion: Structural Innovation for a Low-Carbon Future

MiniMass exemplifies how emerging digital technologies and thoughtful engineering can address the urgent sustainability needs of the construction sector. By drastically cutting carbon, cost, and waste, and enabling bespoke, future-proof structures, MiniMass accelerates the industry’s evolution toward a regenerative built environment. As both materials science and additive manufacturing mature, such breakthroughs could become the standard rather than the exception.

References

- https://orbit.dtu.dk/en/publications/minimass-a-new-approach-for-low-carbon-low-cost-3d-printed-concre

- https://www.minimass.net

- https://www.kompassi.org/wp-content/uploads/2023/01/Teknologia-Eravalo-betaversio-18-01-2023.pdf

- https://www.concretecentre.com/Specification/Innovative-concrete/Minimass.aspx

Read full bio of Sneha Tete