Life Cycle Assessment: Understanding Environmental Impacts from Cradle to Grave

An in-depth look at how Life Cycle Assessment measures, analyzes, and compares the environmental impact of products and processes.

What Is Life Cycle Assessment (LCA)?

Life Cycle Assessment (LCA) is a systematic approach for evaluating the environmental impacts associated with all stages of a product’s life, spanning from raw material extraction (‘cradle’) to final disposal (‘grave’). Through a combination of scientific analysis and data collection, LCA helps organizations, governments, and individuals make informed decisions about sustainability, product design, and resource management by providing insights into the ecological footprint of goods and services.

- LCA quantifies environmental effects at each step of production, use, and end-of-life.

- Encompasses a broad array of impacts such as carbon emissions, energy consumption, resource depletion, and waste management.

- Supports better choices for businesses and consumers by highlighting the hidden environmental costs of materials and processes.

Why Is Life Cycle Assessment Important?

LCA is critical for understanding the full spectrum of a product’s environmental impact — not just at the factory gate, but throughout its entire existence. By focusing on life cycle thinking, LCA seeks to:

- Prevent problem shifting (solving one environmental issue while inadvertently creating others elsewhere in the product chain).

- Enable comparable assessments between different products, materials, or processes.

- Guide eco-design, policy development, and sustainable procurement decisions.

How Does Life Cycle Assessment Work?

LCA follows an internationally standardized methodology (ISO 14040 and ISO 14044) designed to ensure robust, repeatable, and transparent results. The process is divided into four main phases, each with specific goals and activities:

| Phase | Main Activities | Key Questions Addressed |

|---|---|---|

| 1. Goal and Scope Definition | Set objectives, determine boundary and system, pick impact categories | What is being studied and for what purpose? What will be included? |

| 2. Life Cycle Inventory (LCI) | Gather and quantify material, energy, and emission data | What resources are used and what emissions are generated? |

| 3. Life Cycle Impact Assessment (LCIA) | Evaluate effects on environment by translating inventory data into impacts | What are the potential impacts on climate, air, water, and land? |

| 4. Interpretation | Analyze results, draw conclusions, identify limitations and opportunities | What do the results mean, and how can they inform decisions? |

Within these phases, practitioners must define a functional unit (what, exactly, is being assessed – for example, one liter of milk or one smartphone), set system boundaries (which processes are included or excluded), and ensure data quality.

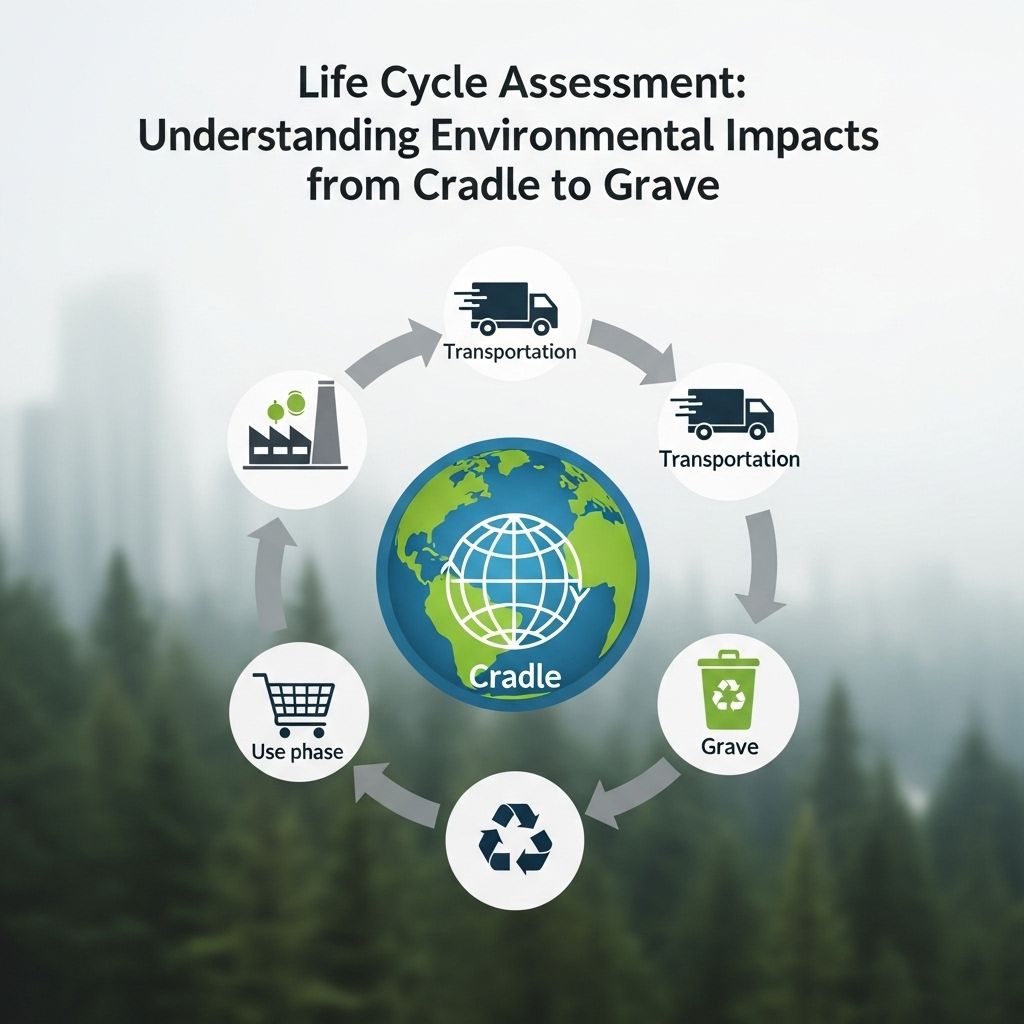

Life Cycle Stages: From Cradle to Grave

To capture the total environmental impact, LCA examines every step in a product’s journey:

- Raw Material Extraction — Mining, harvesting, or sourcing of inputs.

- Manufacturing and Processing — Converting raw materials into finished goods.

- Distribution and Transportation — Moving products between locations, which can occur between each stage.

- Use and Retail — The product’s operational life, including user maintenance.

- End-of-Life Management — Disposal (landfilling, recycling, incineration, composting, etc.).

Variants of LCA Models

LCA assessments can differ based on scope and purpose:

- Cradle-to-Grave: Full life cycle, from resource extraction to disposal.

- Cradle-to-Gate: Assessment stops when the product leaves the manufacturer (excluding user and disposal phases).

- Cradle-to-Cradle: A circular perspective in which end-of-life disposal transitions to recycling or re-use, effectively closing the loop.

The 4 Main Phases of Life Cycle Assessment

1. Goal and Scope Definition

This phase determines the purpose, intended audience, and boundary conditions of the study. Key decisions include:

- What environmental questions are being addressed?

- Which product or process is under assessment?

- What will be included or excluded (system boundaries)?

- Selection of impact categories (e.g., climate change, water use)

- Standardization via ISO 14040/44 guarantees comparability across studies.

2. Life Cycle Inventory (LCI)

The inventory phase compiles all quantitative data relating to material flows and emissions:

- Amounts of materials, energy used throughout each life cycle stage.

- Emissions to air, water, landfill, and other outputs.

- Breakdown by activity, location, and unit process.

Accuracy is paramount; poor inventory data leads to unreliable results. Practitioners typically consult scientific literature, supplier information, and site-specific measurements to make sure data matches the real system.

3. Life Cycle Impact Assessment (LCIA)

Inventory data are translated into understandable environmental impacts. Assessment involves:

- Classification — Linking inventory flows (e.g., CO₂, SO₂) to environmental impact categories (e.g., climate change, acidification).

- Characterization — Quantifying the contribution of individual flows to these impacts using scientifically agreed conversion factors.

- Weighting — Sometimes, impacts in different categories are compared based on relative importance to decision makers.

For example, a life cycle impact assessment can help compare how much “smog formation” or “water toxicity” a product generates against greenhouse gas emissions, placing diverse effects on normalized scales.

4. Interpretation

In this phase, practitioners analyze results, draw conclusions, and make recommendations:

- Identify significant issues (hot spots where impacts are highest).

- Evaluate the completeness and sensitivity of the study.

- State limitations and uncertainties due to data, scope, or method choices.

- Provide informative conclusions for action, improvement, or further research.

Interpretation helps organizations avoid “jumping to conclusions” by presenting results in an informed, relative context. Continuous interpretation as inventory and impact data accrue is encouraged for complex assessments.

Applications and Benefits of LCA

LCA is a versatile tool with broad applications in industry, policymaking, and everyday consumer choices:

- Product and Process Improvement: Pinpoint parts of the value chain with highest environmental cost to facilitate improvement (e.g., optimizing manufacturing or switching to greener materials).

- Eco-Design: Helps designers create products with a lower life-cycle footprint from the outset.

- Business Certification and Communication: Provides verifiable data for Environmental Product Declarations (EPDs), sustainability reports, and competitive comparisons.

- Policy Development: Informs governmental regulation, standards creation, and green procurement policies.

- Consumer Education: Supports more informed purchasing by comparing true sustainability of various options.

Challenges and Limitations of LCA

While LCA is a powerful methodology, it is not without its drawbacks and challenges:

- Data Intensity: Requires accurate, site-specific, and up-to-date inventory data for credible results.

- Complexity of Boundary Setting: Defining what is inside or outside the system can dramatically affect outcomes.

- Assumptions and Uncertainty: Many assessments involve estimates and assumptions, introducing uncertainty.

- Lack of Social and Economic Impact: Conventional LCA focuses on environmental dimensions; broader life cycle sustainability assessment may include social and economic effects.

- Potential for Misinterpretation: Results are highly context-dependent – ‘sustainable’ in one region may not be elsewhere.

Variations: Social Life Cycle Assessment (SLCA) and Beyond

LCA methodology has broadened to address not just environmental but also social and economic impacts:

- Social Life Cycle Assessment (SLCA): Examines the socioeconomic footprint of products, tracking impacts on workers, communities, consumers, and value chain actors.

- SLCA adapts ISO approaches, deploying indicators such as labor conditions, human rights, and community wellbeing.

- Life Cycle Sustainability Assessment (LCSA): Aggregates environmental, social, and economic evaluation for a more holistic view.

Frequently Asked Questions (FAQs)

Q: What does LCA stand for?

A: LCA stands for Life Cycle Assessment, a scientific method that measures and analyzes the environmental impact of products or services across their entire lifecycle.

Q: Which stages are included in a typical life cycle assessment?

A: Most LCAs include raw material extraction, manufacturing, transportation, use, and end-of-life steps such as disposal, recycling, or composting.

Q: How is ‘cradle-to-gate’ different from ‘cradle-to-grave’?

A: Cradle-to-gate stops evaluating a product’s impact once it leaves the factory (before use/disposal), while cradle-to-grave traces every phase including consumer use and final disposal.

Q: Why would a business use LCA?

A: Businesses use LCA to make sustainable choices, identify ways to reduce costs and emissions, qualify for eco-labels, and communicate their environmental performance credibly.

Q: What are some limitations of LCA?

A: Limitations include complexity, reliance on quality data, need for clear system boundaries, and the fact that it generally does not capture social or economic impacts unless specifically extended.

Conclusion

Life Cycle Assessment is an essential tool for anyone wanting to quantify the true sustainability of products and processes. Though challenging, its rigorous methodology and cradle-to-grave perspective offer a more accurate picture than snapshot measurements. As industries and societies strive for sustainability, LCA continues to evolve and expand — integrating social, economic, and environmental factors for holistic improvement across global supply chains.

References

Read full bio of medha deb