A Comprehensive Guide to Carbon Emissions of Building Materials

Explore the environmental impact of building materials and discover sustainable alternatives making a difference.

Understanding Carbon Emissions in Building Materials

The built environment is a principal driver of global carbon dioxide (CO2) emissions, and the selection of building materials plays a significant role in shaping this footprint. Each stage, from raw material extraction to manufacturing, transportation, and construction, contributes to a material’s embodied carbon—the sum of greenhouse gas emissions generated during its lifecycle. As concerns about climate change intensify, understanding and minimizing the carbon cost of building materials is essential for architects, developers, and homeowners alike.

Why Embodied Carbon Matters

When considering carbon emissions in construction, two concepts stand out:

- Embodied Carbon: The greenhouse gases released during a material’s extraction, processing, transportation, manufacturing, installation, maintenance, and disposal.

- Operational Carbon: The emissions associated with the use phase of the building, mostly from heating, cooling, and energy consumption.

With progress in energy-efficient design reducing operational emissions, the embodied carbon in materials now accounts for a larger share—sometimes up to 50% of a new building’s total emissions. Prioritizing low-embodied-carbon materials is becoming an urgent climate strategy.

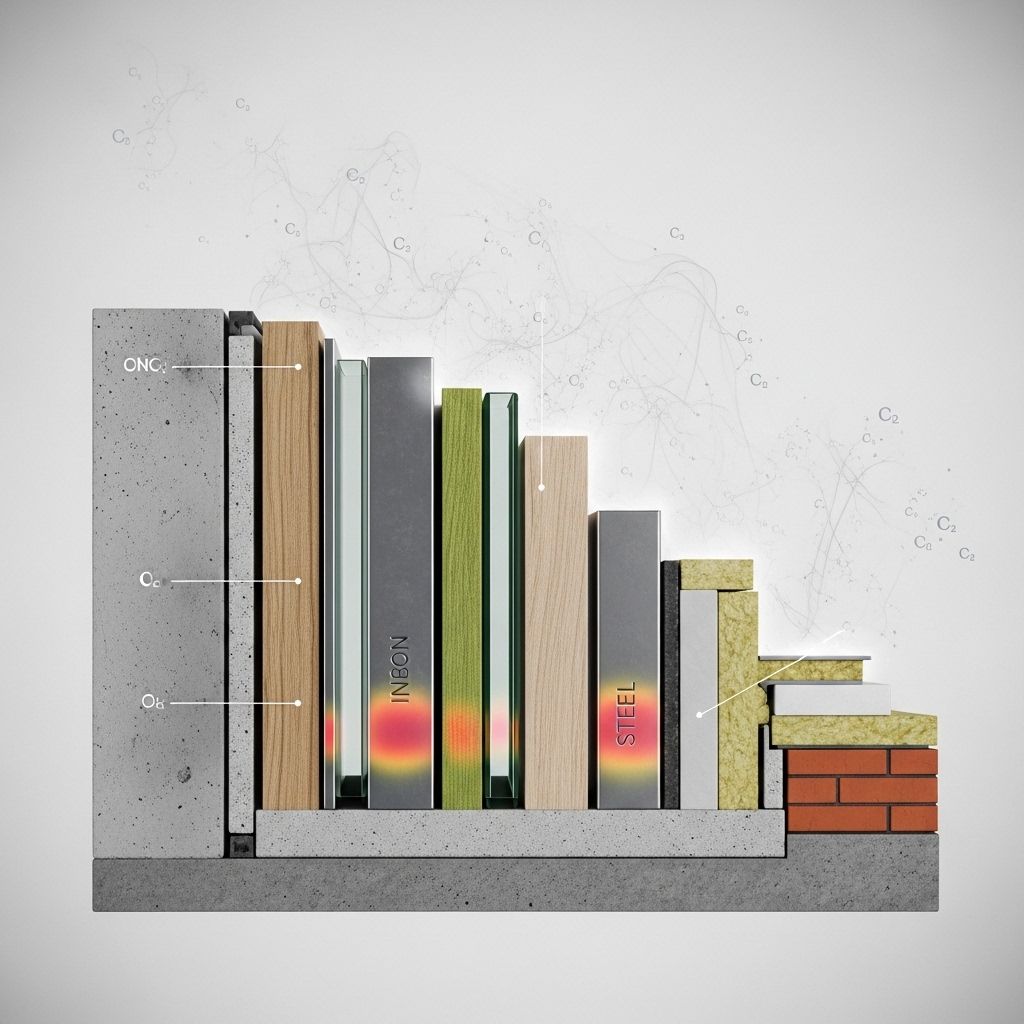

Key Drivers of Emissions in Common Building Materials

Different building materials vary drastically in their carbon impact due to energy-intensive production methods, transportation distances, and resource extraction. Let’s examine how several widely-used materials compare.

| Material | Average Embodied Carbon (kg CO2/m3) | Main Carbon Drivers | Major Uses |

|---|---|---|---|

| Rammed Earth | 48 | Compaction of natural soils, minimal processing | Walls, eco housing |

| Softwood Timber | 110 | Sawmilling, drying, transportation | Framing, flooring |

| Cross Laminated Timber (CLT) | 219 | Lumber processing, gluing | Walls, floors, multi-story structures |

| Stone | 237 | Quarrying, transportation | Walls, facades |

| Clay Brick | 345 | Firing clay in kilns, shaping | Walls, decorative accents |

| Reinforced Concrete | 635 | Cement production, steel reinforcement | Foundations, structure, slabs |

| Steel | ~1,800* | Ore mining, coke firing, smelting | Beams, columns, large structures |

*Steel’s embodied carbon varies greatly based on production method and recycled content.

Low-Carbon Building Materials Explained

Some traditional and emerging materials offer surprisingly low carbon footprints due to minimal processing and natural carbon storage.

1. Rammed Earth

This ancient technique, involving compressed layers of earth, chalk, lime, and gravel, stands out for its ultra-low embodied carbon (about 48 kg CO2/m3), durability, and minimal waste. While its structural uses are limited, it’s regaining popularity for environmentally focused construction.

2. Softwood Timber and Cross Laminated Timber (CLT)

Wood products act as carbon sinks, storing CO2 absorbed by trees. Softwood timber (about 110 kg CO2/m3) and engineered CLT (219 kg CO2/m3) are both lightweight, efficient, and enable rapid construction. Their overall benefit relies on responsible forestry and end-of-life management, preventing the re-release of stored carbon.

3. Stone

Although quarrying and transportation can be energy-consuming, stone’s embodied carbon is relatively low (237 kg CO2/m3) considering its extreme durability. Stone structures can last centuries, spreading their footprint across generations.

Moderate to High-Carbon Materials

4. Clay Brick

Used since ancient times, clay bricks have a moderate carbon footprint (345 kg CO2/m3) due to the energy needed to kiln-fire the clay. Their durability and thermal mass are beneficial in many climates.

5. Reinforced Concrete

Concrete is the most common building material on earth, but its manufacture—especially of cement, a major ingredient—is extremely carbon-intensive. Cement production alone accounts for as much as 8% of global CO2 emissions. Reinforced concrete’s footprint averages 635 kg CO2/m3. While it is strong and flexible, its widespread use magnifies its environmental impact.

6. Steel

Steel is praised for its structural strength and recyclability, but its traditional production is highly energy-intensive, relying on fossil fuels. Its embodied carbon can exceed 1,800 kg CO2/m3 unless high levels of recycled content are used. Innovative steel recycling methods are making environmental inroads, but new steel remains a major emitter.

Comparing Wood, Concrete, and Steel

Multiple life cycle assessments (LCA) of building structures confirm these trends. Replacing steel and concrete with mass timber can reduce greenhouse gas (GHG) emissions from the structure by 65–75%. For example, in one study of a large building:

- Production of concrete made up about 70% of the total GWP (global warming potential) in both timber and steel structures.

- Timber construction (CLT) emitted 75% less CO2 than an equivalent reinforced concrete structure, and even more compared to a steel structure with concrete floors.

- Product stages such as raw material extraction, manufacturing, and transportation (LCA product stage A1–A3) showed roughly 36% lower GHG emissions in the mass timber structure compared to steel.

Despite timber’s sustainability promise, responsible forestry and careful life cycle management are crucial to ensure long-term carbon storage and avoid environmental damage.

Innovations: Low-Carbon Concrete and Hybrid Solutions

The construction sector is engineering new ways to slash embodied carbon:

- Fly Ash and Supplementary Cementitious Materials (SCMs): Replacing part of the cement in concrete with SCMs such as fly ash or slag dramatically cuts CO2 output.

- Phase Change Materials (PCM): Integrating PCM into green buildings and combining with fly ash cement can reduce both carbon emissions and improve thermal efficiency, cutting operational energy consumption for heating and cooling by up to 15% in some scenarios.

- Recycled and Upcycled Materials: Using reclaimed wood, recycled steel, and crushed concrete further lowers embodied emissions by minimizing new raw material extraction.

These strategies, when paired with smart architectural design, can offer truly low-carbon structures for the future.

Making Informed Sustainable Choices

Choosing the right material depends on not only its carbon footprint but also on context, function, and longevity. Here are key factors to consider:

- Source Locally: Transportation can amplify a material’s emissions considerably—local materials reduce this footprint.

- Opt for Renewable, Recycled, or Salvaged Materials: These options help close the carbon loop, keeping emissions lower throughout the lifecycle.

- Design for Durability: Materials that last decades or centuries effectively distribute their carbon impact across a long service life.

- Responsible Sourcing: Certified wood (e.g., FSC or PEFC), reclaimed materials, and suppliers with transparent environmental policies are best where available.

Challenges and Limitations in Reducing Embodied Carbon

- Data Gaps: Many materials and products still lack accessible or standardized carbon footprint data.

- Trade-offs: Lower embodied carbon may sometimes conflict with lifespan, cost, or performance requirements.

- Recycling Barriers: Not all materials are easily recyclable locally, and some recycled products may have lower strength or durability.

- End-of-Life: If carbon-storing materials like wood are burned or left to rot at end-of-life, stored carbon is released back to the atmosphere.

Quick Reference: Sustainable Options Ranked By Carbon Emissions

- Lowest: Rammed Earth

- Softwood Timber

- Cross Laminated Timber (CLT)

- Stone

- Clay Brick

- Reinforced Concrete

- Highest: Steel

Consult embodied carbon databases such as ICE (Inventory of Carbon and Energy) for more detailed numbers on a variety of materials and geographic regions.

Frequently Asked Questions

Q: Why is concrete so carbon intensive?

A: The manufacture of cement, which binds concrete, involves heating limestone to high temperatures, releasing CO2 both from energy used (usually fossil fuels) and from chemical reactions during the process. Concrete’s widespread use magnifies its cumulative environmental cost.

Q: Can wood buildings be truly carbon negative?

A: Timber construction can act as a carbon sink, but only if the forests are sustainably harvested, the wood is reused or recycled at end-of-life, and deforestation or land-use change emissions are prevented. Disposal by incineration or decay releases stored CO2 back into the atmosphere.

Q: Is recycled steel better for the environment?

A: Yes, recycled steel substantially lowers embodied carbon compared to new (virgin) steel, because it uses far less energy. However, steel’s intrinsic emissions remain relatively high compared to renewable materials like wood.

Q: How do I find low-carbon materials for my project?

A: Use embodied carbon databases, seek third-party certifications (like FSC for wood), consider local and reclaimed materials, and consult with sustainability-focused architects or engineers.

Q: Do innovative materials like hempcrete or straw bales have lower emissions than conventional options?

A: Yes, many alternative materials such as hempcrete, straw bales, and bamboo exhibit very low embodied carbon and additional benefits like carbon sequestration. Assess each for local availability and compliance with building codes.

Conclusion: Reducing the Carbon Footprint of Our Built World

Every construction material decision shapes the planet’s future. Dramatically reducing embodied carbon is achievable by favoring low-impact materials, prioritizing responsible sourcing and recycling, and embracing smart, energy-efficient design. As awareness, data availability, and innovation grow, the sustainable building material choices we make today will define tomorrow’s greener, more climate-resilient infrastructure.

References

- https://pliteq.ae/news/building-vs-carbon-footprint/

- https://www.fpl.fs.usda.gov/documnts/pdf2024/fpl_2024_hemmati002.pdf

- https://pubmed.ncbi.nlm.nih.gov/39348018/

- https://www.thelumberbaron.com/carbon-footprint-green-building-materials/

- https://circularecology.com/embodied-carbon-footprint-database.html

- https://rmi.org/embodied-carbon-101/

- https://community.carbonleadershipforum.org/t/ranking-of-top-embodied-carbon-materials-in-buildings/7873

- https://healthymaterialslab.org/tool-guides/the-construction-material-pyramid

Read full bio of Sneha Tete