A Floating Foam Foundation System: Wrapping the House from the Bottom Up

Legalett's floating foam foundation revolutionizes Passive House standards, maximizing insulation and eliminating thermal bridges from the ground up.

Floating Foam Foundations: Innovation Beneath Our Feet

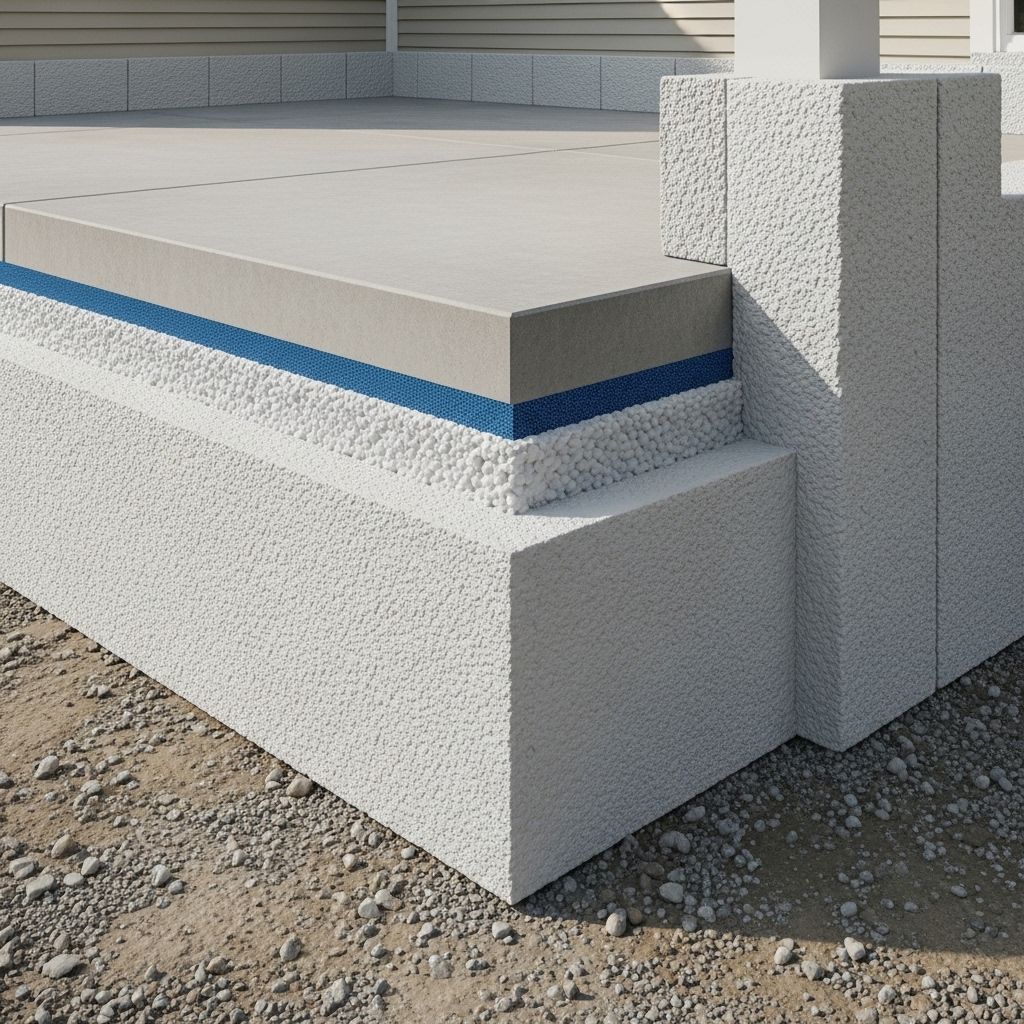

Modern green building demands new approaches to maximizing energy performance and sustainability. In the pursuit of building envelopes with heightened airtightness and insulation—especially for rigorous standards like Passive House—avoiding heat loss at the foundation has become pivotal. The Legalett floating foam foundation insulation system introduces a disruptive yet elegant solution: it quite literally wraps the house from the bottom up with a continuous, thick layer of expanded polystyrene (EPS) foam.

Why Foundations Matter in Sustainable Design

In cold climates, foundations represent a notorious challenge: simple concrete slabs and frost walls can produce significant thermal bridges—hidden pathways for heat to escape. Traditional designs require thick, heavily insulated walls or complex layering to minimize this, yet these methods are often labor-intense, costly, or only partially effective. Legalett, with Swedish roots and North American expansion, offers a holistic solution by literally creating a bathtub-shaped EPS foam shell under and around the slab, all but eliminating these vulnerability points.

- Thermal bridges create weak spots in insulation where heat escapes, reducing energy efficiency.

- Conventional slab-on-grade or foundation designs often struggle to provide continuous insulation, especially at edges and junctions.

- In cold climates, this means significant heat loss, higher energy bills, and difficulty achieving Passive House or Net Zero performance targets.

EPS: The Heart of Legalett’s System

Legalett’s system employs expanded polystyrene (EPS) foam extensively—a material selected for its excellent insulation value, relative environmental benignity, and key physical properties. EPS used in the Legalett system distinguishes itself among foams by utilizing pentane as the blowing agent, substantially reducing greenhouse gas impact compared to HFC-based alternatives. Current and upcoming production shifts will use even less toxic flame retardants, aligning North American EPS with Europe’s more stringent health and safety standards.

- EPS foam delivers high R-values, critical for achieving foundation insulation targets.

- Legalett foam is available without some traditional flame retardants and is transitioning to safer versions commonly used in Europe.

- Pentane-blown EPS has minimal impact on global warming, setting it apart from other insulation foams.

Eliminating the Frost Wall: How Legalett’s Bathtub Design Works

The hallmark feature of the Legalett foundation is its continuous insulated “bathtub”. Rather than the conventional separately poured footing and slab, this system floats the concrete slab in a custom-shaped EPS shell:

- A double layer of dense EPS covers the full footprint of the foundation.

- At the slab’s edge, a specially shaped component curves upward to envelop the slab’s edge without interruption.

- This upward curve enables the insulation of the wall to directly join with the slab foam, truly eliminating the last remnant of a thermal bridge.

This design means there’s no exposed concrete to conduct winter’s cold into the heated space, no footings acting as energy leaks, and a platform for slab-on-grade construction that is especially appropriate for Passive House and other ultra-low-energy buildings.

Case Study: Ottawa’s Passive House Multifamily Project

In a real-world application, Legalett’s floating foam foundation was used beneath a large, four-story, 42-unit affordable housing project in Ottawa. The client’s mission was to meet stringent Passive House criteria. Here, the system’s key strengths were vividly demonstrated:

- Continuous edge insulation eliminated heat loss at the foundation-to-wall transition—often the Achilles’ heel of energy-efficient design.

- Installation simplicity allowed fast, accurate completion—components arrive pre-engineered for the project, minimizing jobsite waste and labor complexity.

- The result was a tightly sealed, highly insulated base platform, supporting both affordable construction and exceptional performance.

How the System Fits into High-Performance Envelopes

Cold-climate buildings, especially those targeting Passive House, LEED Platinum, or Net Zero certification, increasingly require R-values that traditional construction simply cannot achieve. Legalett’s solution directly addresses this challenge by:

- Allowing continuous insulation from the foundation slab upward, avoiding breaks or gaps.

- Serving as a “universal” base for above-ground wall assemblies—compatible with insulated concrete forms, wood framing, or other wall types.

- Streamlining the transition between different insulation layers, without fussy or expensive bracket systems.

Up the Wall: Legalett’s ThermalWall PH Panel

Recognizing that walls present many of the same thermal bridge issues as foundations, Legalett introduced the ThermalWall PH panel, an innovative insulation panel designed specifically for Passive House performance:

- EPS foam block with a removable piece concealing a steel channel for secure mounting.

- Available in a range of thicknesses—for example, a 7-inch panel delivers R-28 continuous insulation.

- After screwing through the steel channel into the building structure, the foam insert snaps back to cover any possible bridge—resulting in zero thermal bridging, even at fasteners.

- Exterior strapping can also be mounted through the same channel, keeping all structures supported but isolated from the cold exterior.

This not only simplifies construction, but it eliminates solutions like long costly screws or suspension brackets (for example, Cascadia Clips), which were previously necessary to support thick exterior insulation. The system is compatible with nearly any wall backing and can upgrade a standard R-24 wall to an R-52 performance envelope.

Environmental and Material Considerations

While many green builders are cautious about foam insulation due to concerns about lifecycle impact and chemical additives, not all foams are created equal. EPS, particularly when upgraded with improved flame retardants and pentane blowing agents, offers several advantages:

- Lower global warming potential compared to HFC-blown foams or polyisocyanurate.

- Recyclability and durability—the foam can last the building’s lifetime.

- Choice of low-impact additives and ongoing improvements in manufacturing further minimize health risks and toxicity concerns.

Continuous Insulation: Key Advantages

| Feature | Conventional Foundation | Legalett Foam Foundation |

|---|---|---|

| Thermal Bridging | Common at wall/slab junctions and footings | Virtually eliminated with full EPS wrap |

| Airtightness | Often weak at slab edge, hard to seal | Continuous foam provides high airtightness |

| Installation Complexity | Multiple steps, potential for gaps and errors | Prefabricated, straightforward assembly |

| Insulation Value (R-Value) | Limited by standard construction | High R-values with customizable foam thickness |

| Environmental Impact | Higher with HFC/PIR foams, lots of concrete | Pentane-based EPS, reduced concrete with shallow slab |

Installation and Builder Experience

The installation process reflects Legalett’s system thinking. Foam components, engineered and pre-cut for each project, arrive at the site ready to assemble. Installers note:

- Foam pieces interlock to form the base and sides.

- The exterior foam “skirt” extends several feet outward for frost protection, especially important in cold regions where frost heaving can damage shallow foundations.

- Once the EPS shell is set, the concrete slab is poured within, “floating” above grade and thermally isolated from cold soils.

- Legalett also provides guidance on integrating underfloor radiant air heating, though with such high insulation levels, minimal heating input is required.

Potential Drawbacks and Criticisms

Even foam advocates know that no system is without tradeoffs. Concerns with foam insulation systems typically include:

- Material Inputs: EPS is petroleum-based, and although production impacts are low, it does not biodegrade.

- Chemical Additives: Flame retardants are steadily improving but still warrant scrutiny.

- Perceived Overkill: Some argue that with such robust insulation, extra systems like radiant heating add unnecessary complexity and cost.

Despite this, the core benefits of a seamless, robust insulation envelope—along with continuous development in foam chemistry—mean the advantages far outweigh the downsides for high-performance, cold-climate construction.

Integrating with Other Building Systems

Legalett’s foundation and wall systems are universally compatible. The floating foam base pairs with nearly any wall assembly, and the ThermalWall PH panel works for new builds and retrofits. Applications include:

- Single-family passive houses

- Multifamily affordable housing

- Commercial or industrial facilities aiming for Net Zero

This modularity means architects and builders can scale high-performance insulation to any building size, region, or code requirement.

Looking Ahead: The Future of Insulated Foundations

The building industry’s move toward continuous, high-performance building envelopes shows no sign of slowing down. With energy codes tightening and interest in Passive House soaring, solutions like Legalett’s floating foam foundation are becoming mainstream. Expected future trends include:

- Greater use of non-toxic, high-performance additives for foam insulation

- Integration with smart building systems for monitoring and leak detection

- Wider adoption of modular, prefabricated insulation systems to decrease labor and increase precision

Related Reading and Resources

- CLT House by Susan Jones: An exploration of sustainable construction with cross-laminated timber and high-performance insulation.

- Thermal Bridging Explained: Why small details at the foundation matter most in green buildings.

- What is a Passive House?: An introduction to the world’s strictest energy efficiency standard.

Frequently Asked Questions (FAQs)

Q: How does Legalett’s floating foam foundation handle frost in cold climates?

A: The system includes an outward-extending foam skirt at the foundation’s edge, providing frost protection without traditional deep footings. This design is highly effective for cold weather resilience and allows for shallow frost-protected foundations.

Q: Are there health or environmental risks associated with EPS insulation?

A: Legalett’s EPS uses pentane as the blowing agent, significantly reducing greenhouse impacts. North American manufacturers are transitioning to lower-toxicity flame retardants, aligning with strict European standards for safer indoor environments.

Q: What building types are best suited for Legalett foam foundation systems?

A: The system suits any slab-on-grade application, from custom homes to large multifamily projects—especially those targeting Passive House, LEED Platinum, or Net Zero goals.

Q: Can this foam-based strategy work for retrofit and remodeling projects?

A: Yes. The wall panel system in particular can add continuous exterior insulation during renovations, transforming existing walls to new code or Passive House standards without major demolition.

Q: How does it compare cost-wise to conventional insulated foundations?

A: While materials cost can be higher up front, labor savings, energy savings, and performance gains—particularly in cold climates—deliver valuable returns over the building’s lifespan.

Summary: A Simple Yet Profound Leap in Foundation Design

Legalett’s floating foam foundation insulation system represents a paradigm shift: transforming the humble building foundation into an unbroken layer of thermal defense. By wrapping not just floors, but whole walls and structures, in continuous EPS foam, builders and designers achieve new heights in airtightness, insulation, and sustainability. As the drive toward energy-efficient, resilient buildings intensifies, such integrated solutions point toward the future of green construction—under our very feet.

References

- http://www.legalett.ca/FPSF-Radiant-Floor-Heating-PDFs/Legalett-Article-TreeHugger-Reviews-Floating-foam-foundation-insulation-system-wraps-house-from-bottom-up-Loyd-Alter.pdf

- http://www.legalett.ca/eps-foam-panel-wall-insulation-passive-house-zne-leed-nzeb-thermalwall-ph.html

- https://www.youtube.com/watch?v=MiFwJzTDkHs

- https://gwestbuilding.com/project/geo-slab-insulated-frost-protected-shallow-foundation-forms-by-legalett/

- http://www.legalett.ca

- http://www.legalett.ca/floating-slab-forms-garage-shed-outbuildings-geo-pad-footing-foundation-eps-foam.html

- http://www.legalett.ca/news-frost-protected-shallow-foundations-icf-floor-forms-press-releases-net-zero-energy-buildings-slab-on-grade-insulation-leed-air-heated-radiant-systems-passive-house-passivhaus-concrete-homes.html

Read full bio of medha deb