Building Bricks from Textile Waste: FabBRICK’s Sustainable Revolution

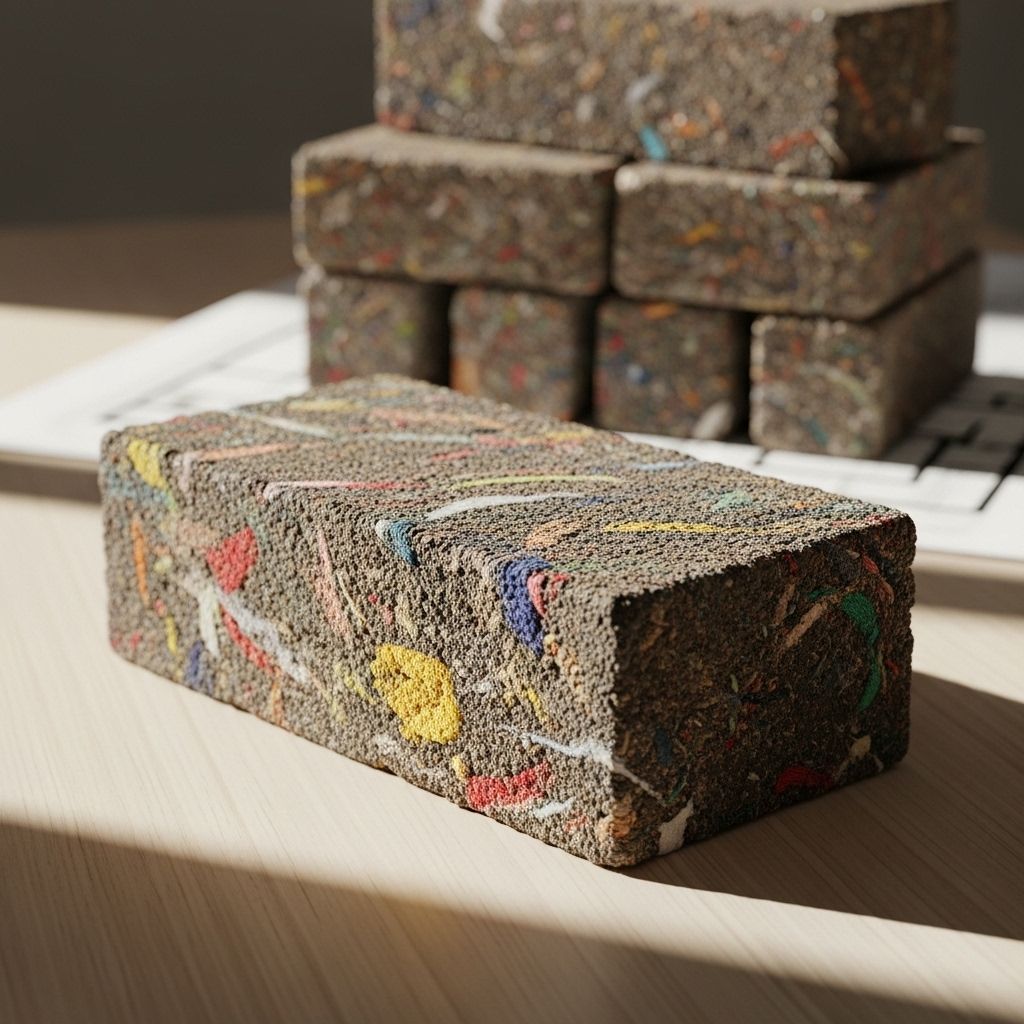

FabBRICK transforms textile waste into eco-friendly, customizable, and elegant building bricks, paving the way for sustainable architecture.

Turning Textile Waste Into Sustainable Bricks

Textile waste is a growing environmental challenge, with millions of tons of old clothes and fabrics sent to landfill each year. Amidst global efforts to mitigate waste and add sustainability to our built environment, FabBRICK, a Paris-based innovation studio, has developed a pioneering architectural material: bricks made entirely from discarded textiles. This breakthrough transforms unwanted fashion into functional, elegant building blocks, promoting circular economy principles in construction.

Why Textile Waste Matters

Globally, textile production and disposal contribute significantly to pollution and landfill overload. Traditional brick manufacturing, meanwhile, consumes clay, water, and energy, yielding high levels of carbon emissions and environmental degradation. Repurposing fabric waste as a raw input for bricks directly addresses these sustainability issues:

- Reduces landfill waste

- Decreases manufacturing emissions

- Protects natural clay and other construction resources

- Promotes creative reuse in design & architecture

FabBRICK’s Vision and Innovation

Founded in Paris, FabBRICK sought to merge aesthetics, sustainability, and practical engineering. Rather than using virgin materials or energy-intensive methods, the process exclusively utilizes unwanted clothing and fabric offcuts. The result: sturdy, stylish bricks suitable for wall panels, partitions, or furniture—each one unique in texture and hue.

How FabBRICK Bricks Are Made

The production of FabBRICK bricks follows a meticulously eco-conscious sequence. Here’s a step-by-step walkthrough:

- Step 1: Collecting Textile Waste

FabBRICK sources discarded clothes and textiles from local suppliers. Fabrics arrive at their Paris studio and are sorted by color and type, setting the foundation for future aesthetics. - Step 2: Selection and Customization

For each project, customers select the desired brick size (FabBRICK offers about 10 standard formats) and the color palette. No artificial dyes are introduced—the final appearance depends on the textiles themselves. - Step 3: Shredding Textiles Into Fibers

Textiles are shredded into fibers of various lengths—7mm, 20mm, and 40mm—chosen based on the intended use. Shorter fibers yield smooth bricks for furniture; longer ones enhance insulation properties. - Step 4: Making Eco-Friendly Glue

FabBRICK uses glue made entirely from ecological ingredients—no harsh chemicals involved. This ensures the bricks are non-toxic and environmentally benign. - Step 5: Mixing and Molding

The shredded fibers and glue are mixed by hand to guarantee uniform density. This mixture is then packed into molds, using a patented machine, and compressed for 30 minutes. - Step 6: Air-Drying

Bricks are left to dry in ambient air for 10-15 days, solidifying naturally without ovens or kilns. This markedly reduces energy usage compared to standard brickmaking. - Step 7: Assembly and Application

Finished bricks can be shipped as units or incorporated into custom furniture, wall partitions, or decorative panels, offering both form and function.

The Science Behind Textile Bricks

The success of textile-based bricks hinges on a few key engineering innovations:

- Compressive Strength: Bricks must withstand building loads. FabBRICK’s mixing and molding techniques ensure even fiber distribution, creating robust, structurally sound blocks.

- Thermal and Acoustic Insulation: Textile fibers naturally trap air, offering superior insulation and sound absorption when used in wall panels and partitions.

- Low Embodied Energy: By avoiding high-temperature kilns and relying on ambient drying, the energy footprint of each brick is drastically reduced.

- Aesthetic Versatility: Because the color comes from the original garments, every brick has a unique look. Designers enjoy flexibility for custom interior palettes—no two bricks are exactly alike.

FabBRICK vs. Traditional Brick: A Comparison

| Feature | FabBRICK | Traditional Brick |

|---|---|---|

| Raw Material | Textile waste | Clay, sand, cement |

| Energy Use | No ovens or kilns | High heat required |

| Water Use | Negligible | High, especially in concrete |

| Emissions | Very low | High CO₂ footprint |

| Color Customization | Based on garment color; infinite options | Generally red/orange, limited finishes |

The Aesthetic & Commercial Edge

Unlike conventional bricks, FabBRICK’s creations are visually distinctive, drawing on the vibrant palette of their original garments. The process yields bricks suitable for:

- Wall coverings: Standard sizes (e.g., 20 x 10 x 2.5 cm) allow for easy installation in commercial or residential interiors, with built-in insulation benefits.

- Furniture: Modular bricks can form chairs, tables, or decorative elements, leveraging the strength and color diversity of textile fibers.

- Partitions: Durable enough for non-load-bearing walls, these bricks support flexible workplace layouts or retail displays.

Interior designers value the product for its unique color patterns and environmental messaging; brands see an opportunity to communicate sustainability without sacrificing style.

Scaling Sustainability: Production & Impact

Since launching, FabBRICK has produced over 40,000 bricks, partnered with global brands, and actively raised awareness on reducing textile waste’s environmental consequences. This scalable approach has several broader benefits:

- Repurposes thousands of kilograms of textile waste annually

- Minimizes water, energy, and resource consumption

- Supports green innovation and the circular economy within construction

Additional research supports the trend: fabric waste bricks made with clay or soil as a binder demonstrate impressive durability and further potential for widespread adoption in building.

Environmental and Social Advantages

- Waste Diversion: Keeps clothing out of landfill and incinerators, directly shrinking the textile footprint.

- Climate Mitigation: Lowers greenhouse gas emissions—no high-heat ovens, no mining of clay.

- Local Resource Use: Sources materials locally and employs hands-on, artisanal production in Paris.

- Community Engagement: Invites customers to participate in color and format selection, linking sustainability with personal design.

FabBRICK’s Products and Use Cases

Currently, FabBRICK focuses on several applications:

- Handmade Wall Panels: Ideal for retail stores, offices, and homes where insulation and unique color effects are desired.

- Modular Furniture: Chairs, tables, cubes—innovative forms made possible by the brick’s flexibility and visual appeal.

- Interior Partitions: Lightweight, durable walls for subdividing spaces, perfectly matched to custom finishes and branding.

All options allow customization—a direct reflection of a customer’s sustainability values, aesthetic priorities, and space needs.

Frequently Asked Questions (FAQs)

Q: What are FabBRICK bricks made from?

A: FabBRICK bricks are made from shredded textile waste and 100% ecological glue. No harsh chemical binders, and no dyes are used; color comes from the textiles themselves.

Q: Are these bricks suitable for load-bearing walls?

A: FabBRICK bricks are best used for partitions, wall covers, and furniture—not typically for heavy structural walls. Research on fabric-brick mixtures with clay shows promise for increased compressive strength, potentially suitable for certain construction contexts.

Q: How does the process compare to traditional brickmaking?

A: FabBRICK avoids energy-intensive kilns, toxic chemicals, and high water use associated with traditional brickmaking. Their process uses only ambient air for drying and relies on recycled fibers for color.

Q: How long does it take to produce a brick?

A: The glue-fiber mixture is compressed for 30 minutes, then bricks dry in open air for 10-15 days before use.

Q: Can customers customize the look and size of their bricks?

A: Yes. FabBRICK offers multiple formats and allows customers to choose color palettes based on the available textiles, ensuring each project is unique.

The Future: Expanding Sustainable Construction Materials

As cities search for greener methods to build and renovate, textile-based bricks offer a compelling alternative to outdated, resource-heavy supplies. FabBRICK’s process demonstrates how upcycling, local manufacturing, and customer collaboration can reimagine waste as an essential resource. With continued innovation and growing market demand, the hope is that textile bricks will inspire new circular practices across the construction industry—and beyond.

Key Takeaways

- Repurposing textile waste for bricks directly addresses global waste and emissions challenges.

- FabBRICK’s process is low-energy, non-toxic, and highly customizable, merging sustainability with design.

- Visual versatility makes textile bricks attractive to designers and brands, while their environmental footprint is a fraction of traditional alternatives.

- Ongoing research and adoption suggest a growing role for textile-based materials in future construction.

References

- https://designwanted.com/fabbrick-construction-materials-recycled-textile/

- https://www.texspacetoday.com/fabbrick-is-transforming-textile-waste-into-bricks/

- https://www.irjmets.com/uploadedfiles/paper/issue_6_june_2024/59096/final/fin_irjmets1718274685.pdf

- https://parametric-architecture.com/transforming-textiles-into-bricks-fabbrick/

- https://www.winssolutions.org/fabbrick-turns-textile-waste-into-bricks/

- https://www.youtube.com/shorts/jaECeK3KBCc

Read full bio of Sneha Tete