A Breakthrough Battery: Harnessing Cheap, Abundant Materials for Greener Energy Storage

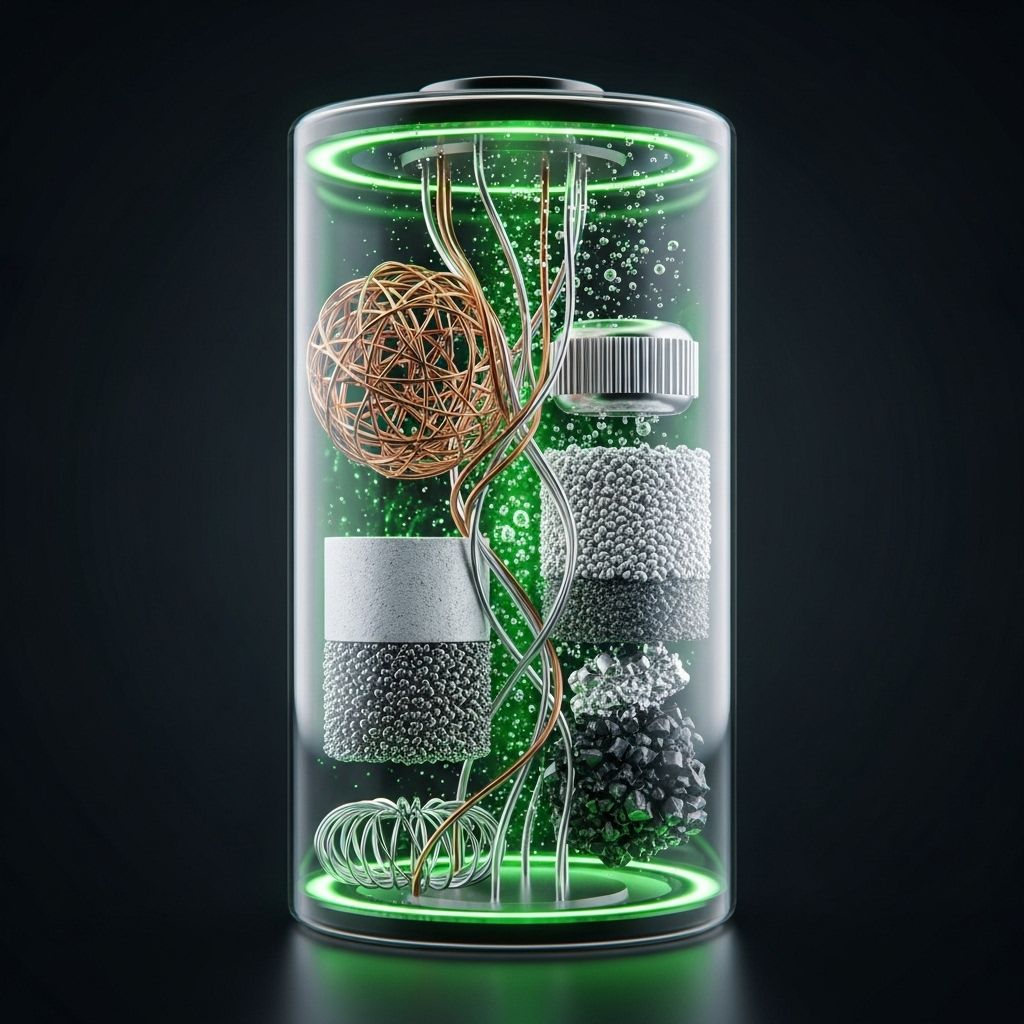

How an innovative aluminum-sulfur battery promises affordable, scalable, and safer renewable energy storage.

A Breakthrough in Affordable Energy Storage

As the transition to renewable energy accelerates worldwide, the challenge of affordable, scalable, and safe energy storage remains urgent. Traditional lithium-ion batteries, while widely used, come with high costs, safety risks, and environmental concerns. Enter a new contender: the aluminum-sulfur battery, built from abundant, low-cost, and non-toxic materials. This promising technology could transform how we store solar and wind power, making green energy more accessible than ever.

Why Modern Batteries Need to Change

Renewable sources like wind and solar are intermittent—they generate electricity only when the wind blows or the sun shines. To support a stable grid and make renewables practical at large scales, energy storage must bridge gaps in production and demand. But the current standard, lithium-ion batteries, faces several hurdles:

- High material costs: Lithium and other key elements used in these batteries are expensive and not always abundant.

- Safety concerns: Lithium-ion batteries use flammable electrolytes and are prone to overheating and fires under some conditions.

- Sustainability issues: Mining and refining lithium pose environmental and ethical challenges.

- Grid-scale limits: For large solar and wind installations, cheaper and simpler alternatives are needed.

The Aluminum-Sulfur Battery: An Overview

The aluminum-sulfur battery was developed to address these shortcomings using three widely available ingredients:

- Aluminum: The most abundant metal on Earth, inexpensive, and commonly used in everyday products.

- Sulfur: An extremely cheap and plentiful element, often produced as an industrial waste byproduct.

- Common salt-based electrolytes: Simple molten salts that conduct ions between electrodes, chosen for safety and affordability.

Rather than expensive or rare metals, all core components can be sourced cheaply and safely. The battery’s architecture minimizes fire risk and environmental impact, making it particularly suitable for renewable energy storage.

Basic Battery Chemistry

The new battery design relies on aluminum as the anode (negative electrode) and sulfur as the cathode (positive electrode), separated by a molten salt electrolyte. During charging and discharge cycles, ions move through the molten salt, storing and releasing energy without the hazards associated with volatile, flammable solvents. The operating temperature is kept just above water’s boiling point, which makes practical, safe battery operation possible without imposing heavy insulation or corrosion challenges.

What Makes This Battery Unique?

A series of features set the aluminum-sulfur battery apart from conventional energy storage solutions:

- Ultra-low cost: Estimated at about one-sixth the price per cell compared to comparable lithium-ion batteries.

- Extraordinary safety: Non-flammable and incapable of thermal runaway fires.

- Fast charging: Able to support rapid charging and discharging, depending on operating temperature.

- Long cycle life: Early tests show hundreds of deep charge-discharge cycles with minimal performance loss.

- Environmental responsibility: All core materials are abundant, with low extraction and processing impacts.

Performance Highlights

- The battery can perform at rapid charging rates, especially at about 110°C (230°F), achieving charging speeds up to 25 times faster than at room temperature.

- Hundreds of cycles have shown strong durability, making it suitable for daily renewable energy shifts.

- The materials used—for example, ordinary aluminum foil and sulfur recovered from petroleum refining—are commodity materials with robust recycling pathways.

How the Battery Works

The aluminum-sulfur battery operates through a simple yet effective process:

- During charging, aluminum ions are driven from the cathode (sulfur) side through the electrolyte and deposited on the aluminum anode.

- During discharge, this process reverses, releasing stored energy back into the grid or device.

- The molten salt electrolyte ensures high ionic conductivity and stability, even at modestly elevated temperatures.

This robust, reversible chemistry allows the battery to deliver high power in short bursts or sustained energy for hours.

Comparing Battery Technologies

| Technology | Key Materials | Cost | Safety | Best Use Case |

|---|---|---|---|---|

| Lithium-Ion | Lithium, cobalt or nickel, copper | High | Risk of fire | Consumer electronics, EVs |

| Aluminum-Sulfur | Aluminum, sulfur, salts | Very low | Non-flammable | Grid/local renewable storage |

| Pumped Hydro | Water, reservoirs | Moderate | Very safe | Large-scale, special locations |

| Sodium-Ion | Sodium, iron, various compounds | Lower than lithium | Moderate | Entry-level grid, backup |

Ideal Applications and Scale

Due to its compact size and robust safety, the aluminum-sulfur battery is well-suited for several critical applications:

- Residential backup: Storing solar or wind energy for use during outages or nighttime.

- Small to medium businesses: Providing affordable storage to support solar roofs or local grid balancing.

- Vehicle charging stations: Enabling rapid, high-amperage refueling of electric vehicles without modifying grid infrastructure.

- Off-grid or microgrid power: Supplying stable, 24/7 electricity in remote or disaster-affected areas.

While more experimental than pumped hydro for utilities, the aluminum-sulfur battery could complement larger installations or serve as a distributed energy resource for millions of buildings.

Environmental and Economic Impact

Beyond inexpensive materials and safety, the eco-benefits of this battery stem from:

- Lowered mining impact: Unlike lithium or cobalt, aluminum and sulfur are easy to source and process without intensive environmental disruption.

- Recycling potential: Both aluminum and sulfur have established recycling streams, further reducing lifecycle emissions.

- Utilization of industrial waste: Sulfur, often a byproduct of oil refining, is turned from waste into a valuable product.

- Reduction in flammable and toxic materials: The salt electrolyte is vastly safer than volatile organic solvents.

This makes the new battery especially attractive for green energy projects, where sustainability, safety, and cost are paramount.

The Vision and Its Inventors

This battery was developed by an international team led by Professor Donald Sadoway at MIT. Sadoway’s research group sought to surpass lithium-ion batteries, targeting affordability, abundance, and safety first. Their iterative approach—surveying the periodic table for ideal candidates—led them to the aluminum-sulfur-salt combination.

Sadoway previously developed the liquid-metal battery for grid storage, which is already approaching commercial deployment. His team’s new invention targets smaller-scale, distributed installations, complementing larger grid-scale technologies.

Challenges and Path to Market

Several obstacles remain before aluminum-sulfur batteries see widespread commercial use:

- Scaling up production: Moving from successful laboratory prototypes to mass manufacturing is complex and requires further investment.

- Durability validation: More long-term cycling and environmental stress testing is needed to ensure a decade or more of reliable performance.

- Integration and regulation: Codes and standards for new battery chemistries must be developed for safety and compatibility.

However, the cost-effectiveness and abundance of core materials provide a strong foundation for broad adoption, especially as energy systems become more distributed and decentralized.

Sustainable Innovation: The Broader Battery Landscape

The aluminum-sulfur battery is one of several new approaches striving to replace or supplement lithium-ion chemistry. Other promising green technologies include:

- Sodium-ion batteries: Using abundant sodium for lower-cost grid and vehicle batteries.

- Lithium iron phosphate (LFP): Already adopted in many EVs for safer, more sustainable performance.

- Organic and solid-state batteries: Incorporating cellulose from trees or other organic compounds for greener electrolytes.

Together, these advancements are poised to democratize energy storage, supporting both the climate transition and affordable resilience in the face of grid disruptions.

Frequently Asked Questions (FAQs)

Q: What are the main advantages of an aluminum-sulfur battery over lithium-ion?

A: Aluminum-sulfur batteries use cheaper, more abundant materials, are much safer (non-flammable), and have a significantly lower projected cost per cell. They are particularly suitable for stationary energy storage for homes, businesses, and renewable grids.

Q: Are these batteries safe to use indoors or in populated areas?

A: Yes, the batteries avoid flammable electrolytes and are designed to be non-combustible and stable at higher temperatures, making them much safer for indoor and densely populated uses than lithium-ion batteries.

Q: How are the materials for this battery sourced?

A: Aluminum is widely available and easily recycled; sulfur is inexpensive and often a waste byproduct from industrial processes; the molten salts are common and simple to manufacture at scale.

Q: Where might we see aluminum-sulfur batteries used first?

A: Likely early adopters include residential battery installations, commercial backup systems, charging station infrastructure, and off-grid or microgrid renewable energy projects.

Q: When could this battery technology be commercialized?

A: Laboratory results are promising, but mass-market commercialization depends on further testing, regulatory approval, and investment in production facilities. Widespread adoption could begin within a few years if current progress continues.

References

Read full bio of medha deb